Internal combustion engines require airflow to generate horsepower; it’s a simple and well-known fact. Typically, the increase in air is facilitated when forced induction is introduced. However, when Ford opened the hood of its 2024 Mustang GT and Dark Horse at the Stampede, there was neither a supercharger nor a turbocharger in sight. Nevertheless, the air induction system extending from the front of the intake manifold boasted two massive 80mm throttle bodies, providing air to a naturally-aspirated Gen-4 Coyote engine.

From a simplistic outlook, the additional throttle body was there to enhance airflow. However, what kind of airflow could a Coyote engine, packing only 5 liters, necessitate over a traditional single throttle body? Well, that answer gets complicated, as the secondary throttle body was not there to increase airflow for performance, but to counteract the effects of new evaporative emission standards and their implementation of hydrocarbon traps. Ford engineers were contending between internal horsepower targets and emission standards. Alas, the solution was simple: double the air intake capacity. Hence, the symmetrical airboxes, intake piping, and throttle bodies.

However, would the answer remain this simple when adding a positive displacement supercharger into the mix? To explore this, we talked with Nick Purciello from Whipple Superchargers.

Engineered For Efficiency

Whipple has experienced a significant surge in popularity over the years, with its positive displacement blowers becoming more efficient with each new generation. The supercharging company has also made notable business moves by collaborating with Ford Performance to develop post-title supercharger kits. For example, the FP700 for the Ford F-150 uses its Gen-5 3.0-liter, and the FP800 kit for the 2024 Mustang sports the all-new Gen-6 3.0-liter. Through these partnerships and enhanced engineering designs, Whipple has developed a keen understanding of how to determine the best way to deliver the maximum horsepower possible for enthusiasts and racers.

The Whipple Gen-6 3.0-liter for the 2024 Mustang was revealed as the supercharger of choice for the FP800S package from Ford Performance.

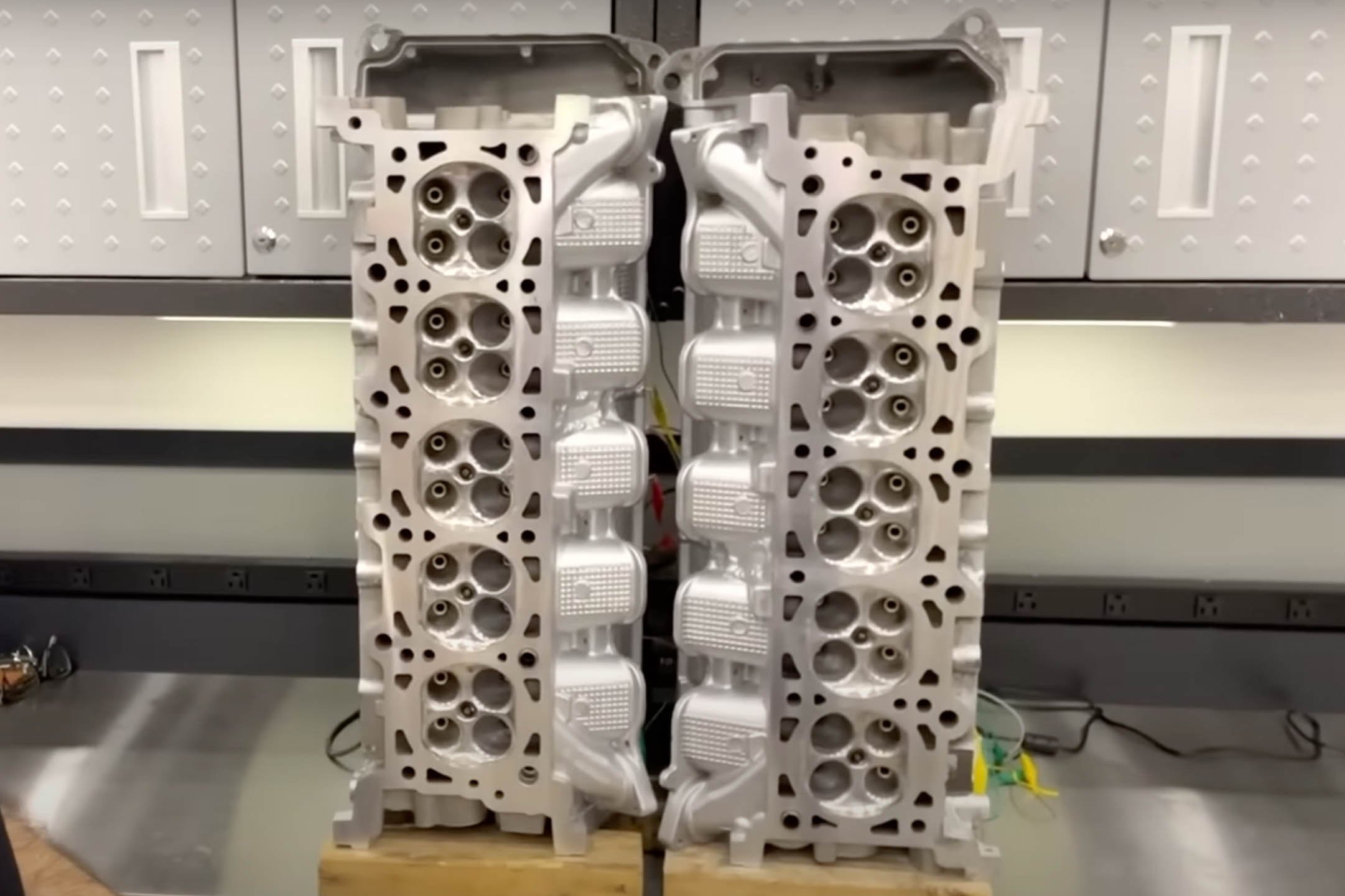

When operating at the scale that Whipple does, more than assumptions precede the production tooling phase. Each variable undergoes thorough testing before being produced. Whipple employs Computational Fluid Dynamics (CFD) software to simulate airflow, optimizing the design to increase efficiency and horsepower figures. The team at Whipple ensures that every design change is run through the CFD software, leaving nothing on the table. This comprehensive approach includes testing the dual throttle inlet concept for a supercharged platform on the 2024 Mustang GT and Dark Horse.

“Initially, our idea was to utilize the two 80mm throttle bodies, as they would provide more than enough airflow for our 3.0-liter supercharger in Stage 1 and Stage 2 trim. It was also important to keep the intake system as symmetrical as possible, but this concept proved to be challenging in multiple ways,” says Purciello. “The CFD results proved the dual inlet concept wasn’t going to meet our standards. Equal airflow distribution and velocity to the supercharger rotors are critical to maximizing performance potential. It was clear that no tweak of this inlet design was going to fix the dead zone created by the pocket that accommodates the supercharger pulley location.”

Achieving equal airflow distribution and velocity to the supercharger rotors is crucial for maximizing performance potential. Whipple's CFD testing conclusively showed that the dual inlet concept wouldn't meet its standards since the dead zone created by the pocket accommodating the supercharger pulley location would significantly reduce airflow to the female rotor, rendering this approach a no-go.

Staying Single

With the idea of a twin throttle body setup fading in the rearview mirror, the next obstacle was to determine if a two-into-one intake system would outperform the traditional single throttle body intake. “The single throttle body inlet is a proven design, so that was the next play. To establish a baseline, we used the existing 150mm ‘roval’ supercharger inlet and designed a two-into-one intake tube that uses both airboxes,” Purciello explains. “We knew one intake was good and were surprised to discover that a two-into-one throttle body was even better for flow.”

Whipple didn’t stop there and began testing throttle body sizes, aiming to perfect and optimize the airflow going to both the male and female rotors. “The 132mm and 150mm throttle bodies do very well with a single intake, but the CFD results of the dual intake pipe showed that we could do better. With the roval 132mm throttle body, there is a larger angle to the face of the supercharger coupled with a downward angle which slightly reduced flow to the male rotor,” Purciello details. “A round throttle opening was the solution and provides similar airflow capability but with a better angle of attack. Airflow calculations concluded we need a 112mm round throttle body to match the 132mm roval, and CFD confirmed the 112 slightly edges out the 132.”

Once determined that a two-into-one intake was the route Whipple wanted to pursue, the next step was deciding on throttle body size and shape. A round throttle opening would offer similar airflow capability with a better angle of attack. Eventually, the data showed that a 112mm round throttle body would match the 132mm roval, and CFD confirmed that the 112mm slightly edged out the 132mm.

Increased Airflow and Surface Area

Depending on the power level you wish to achieve, the Gen-6 3.0-liter kit offered for the 2024 Mustang will be sold with Stage 1 or Stage 2 intake tubes. The Stage 1 will utilize the already proven 92mm throttle body found on the 5.2-liter Predator engine, while the Stage 2 kit will be using the 112mm throttle body mentioned above, but can accommodate up to 120mm. Purciello notes that it is “plenty big enough to flow what the 3.0-liter Gen 6 is capable of.”

Now, you might be thinking that running two air filters is nothing more than a guise or, at the very least, a restriction. Well, you would be correct on the second part, to an extent. “Plain and simple, an air filter is a restriction. We use the highest flowing cotton fiber filters available, but there will always be some pressure drop, especially at higher power levels,” Purciello states. “The unique opportunity provided by the S650 engine bay enabled us to utilize two air filters, greatly increasing the overall airflow potential without having to make physical part changes from our base package.

Having double the air filter surface area is a game-changer and something we wish we could implement in other applications. Nick Purciello, Whipple Superchargers.

As mentioned earlier, the dual intakes from the factory are designed to address emission constraints rather than specifically enhance performance. In contrast, a Whipple supercharger is engineered to generate more power and operating at maximum efficiency is key to this. Achieving this goal necessitates ensuring that the entire intake system is crafted to provide the supercharger with the necessary airflow. According to Purciello, “Whipple’s positive displacement superchargers thrive with minimal restriction in front of them for optimal flow and efficiency.” He adds, “Having double the air filter surface area is a game-changer and something we wish we could implement in other applications.”

Unlike the newly introduced and regrettably more restrictive HCT in the intakes of the S650, Whipple’s HCT will flow through, similar to the setup found in the Shelby GT350 and the 2020 and newer GT500. This design ensures a more optimal airflow.

The Whipple Difference

If Whipple Superchargers invested this much effort into an intake pipe, one can only imagine the extensive testing and refinement they conducted for their supercharger and tuning capabilities in-house and at Ford Performance headquarters in Dearborn, Michigan. The brand consistently emphasizes that their products are built with no compromises and designed for maximum effort. After hearing what Purciello had to say, it’s hard to argue otherwise.