The trucks we use every day are workhorses, and as such, spend a lot of time getting, well, used. Everyone knows that hard parts fail. However, with today’s high-tech haulers, more often than not, if we experience an issue, it is usually with wiring and/or electronics.

We have a 2015 Silverado shop truck that has, unfortunately, encountered some serious issues with the turbo. The 6.6-liter Duramax engine was letting us know it was time for a turbo upgrade. We learned this when the truck encountered what we thought was a Vane Position Sensor (VPS) leaving us stranded. The VPS controls the unison ring and turbo vanes located within the engine’s Garrett turbocharger. This is a common issue amongst the 2004.5 to 2016 Duramax turbo-diesel engines which use variable geometry turbochargers.

Once we dug into it, we soon learned soot build-up inside the turbo was actually causing the truck to run poorly. Since the Silverado was suffering from poor performance and wouldn’t make the boost it should — and since we were going to be knee-deep into the valley of the engine anyway — we thought what better time for a turbo upgrade than right now?

Who You Gonna Call?

Since we were getting in deep, there was no way we would install a stock turbo. C’mon, why would we? To upgrade the boost maker, we had our eyes set on one of Fleece Performance‘s Cheetah turbochargers. For years, Fleece has been at the front of the pack when it comes to stock replacement turbochargers, offering support for virtually every truck you see on the road. We wanted to see if our Duramax could benefit from a Cheetah, and we also wanted to find out what makes their products so popular, so we gave them a call.

We talked with the Vice President Of Sales And Marketing, Jeff Everett, and discussed our situation. We told him what our symptoms were and mentioned doing an upgrade. While corresponding with Jeff about this project, we made it known upfront that our upgrade needed to be stock appearing and conform to California Air Resources Board (CARB) guidelines since the truck is in California.

“After hearing your symptoms, it could be a few things. It could be the Vane Position Sensor or the actuator itself, “Jeff tells us. “Lucky for you, all of our turbochargers come new with both, so you’re going to be fresh anyway. These turbochargers come brand new from Garrett and we then turn them into our Cheetahs.”

As I stated, the truck is located in California, and as such, must meet stringent emissions standards. Luckily, the Cheetah Turbo does that. According to Jeff, “our LML Cheetah turbocharger is legal to use as a replacement turbo as it carries a CARB E.O. number (D-834-3).” With the legalities assured, the upgrade was started.

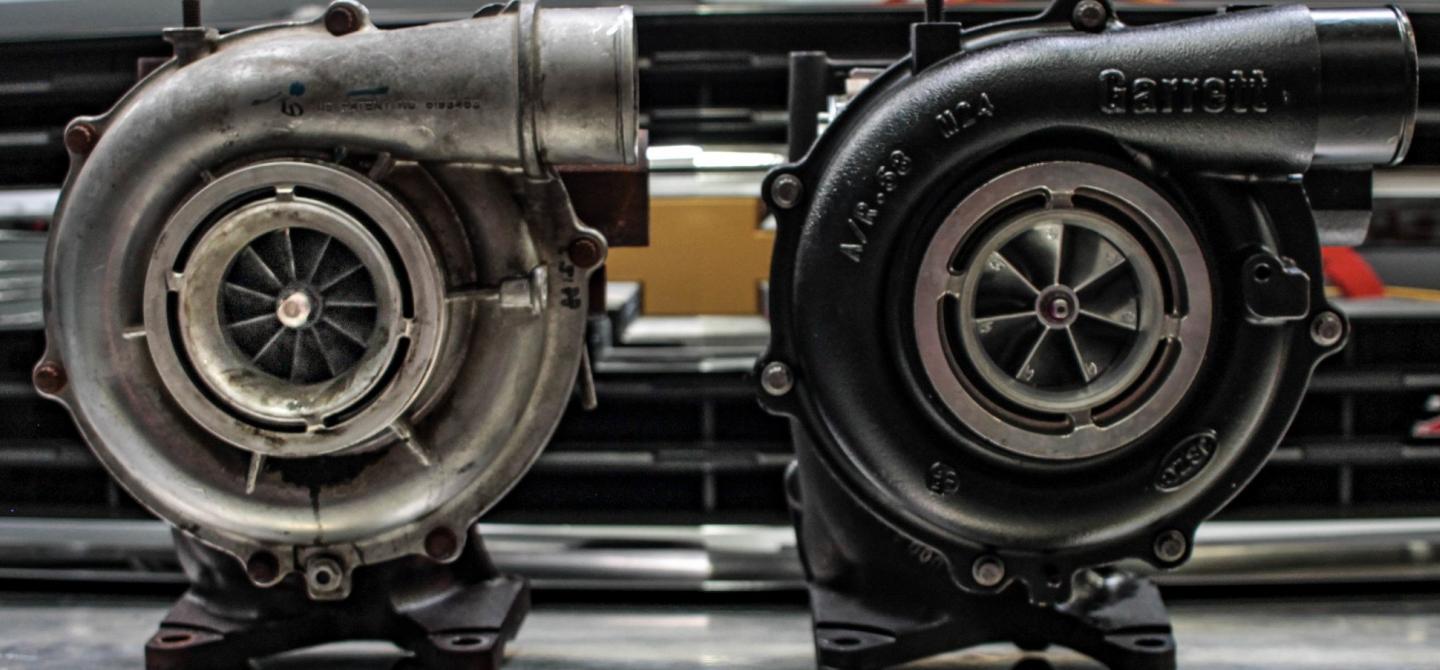

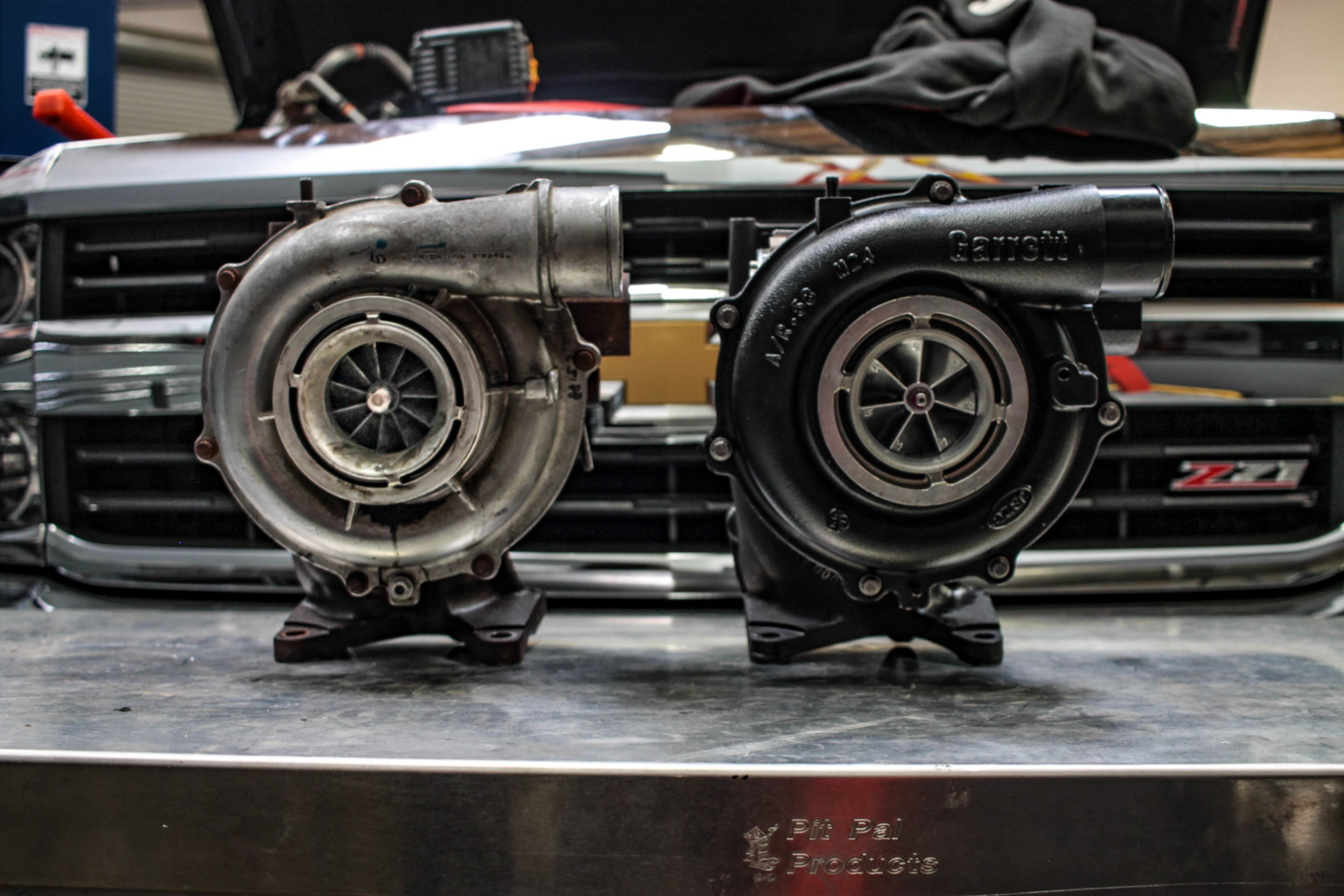

After a few back-and-forth emails, our new Fleece Cheetah arrived. We’ve heard the buzz on various forums about the Cheetah turbo upgrade, but we wanted to find out for ourselves what the hubbub was all about. Frantically tearing the box open, this new turbo looks slick. It is a stock-appearing, 63 mm forged-and-milled-wheel Garrett turbo that is coated in a stealthy black.

It’s Cheetah Time

We were promised a quicker spool-up and throttle response of a smaller turbo while still enjoying the big-end power of a larger one. We needed to upgrade the old worn-out turbo and by the sounds of it, we’re on our way to having a truck that is alot more fun to drive. This turbo is rated at 650 rear-wheel horsepower and it is supposed to be the ultimate combination for dual-purpose applications. You know, it’s right at home on a normal drive and can still handle the rigors of pulling a heavy load.

Benefits And Features

On the outside — minus the slick new paint job — this turbo looks the same as any other. It’s what is on the inside that counts. This turbo upgrade uses a stock housing with updated internals. This allows you to keep all of your factory systems intact, yet affords you the opportunity to run more boost, in fact, nearing the 40-psi mark.

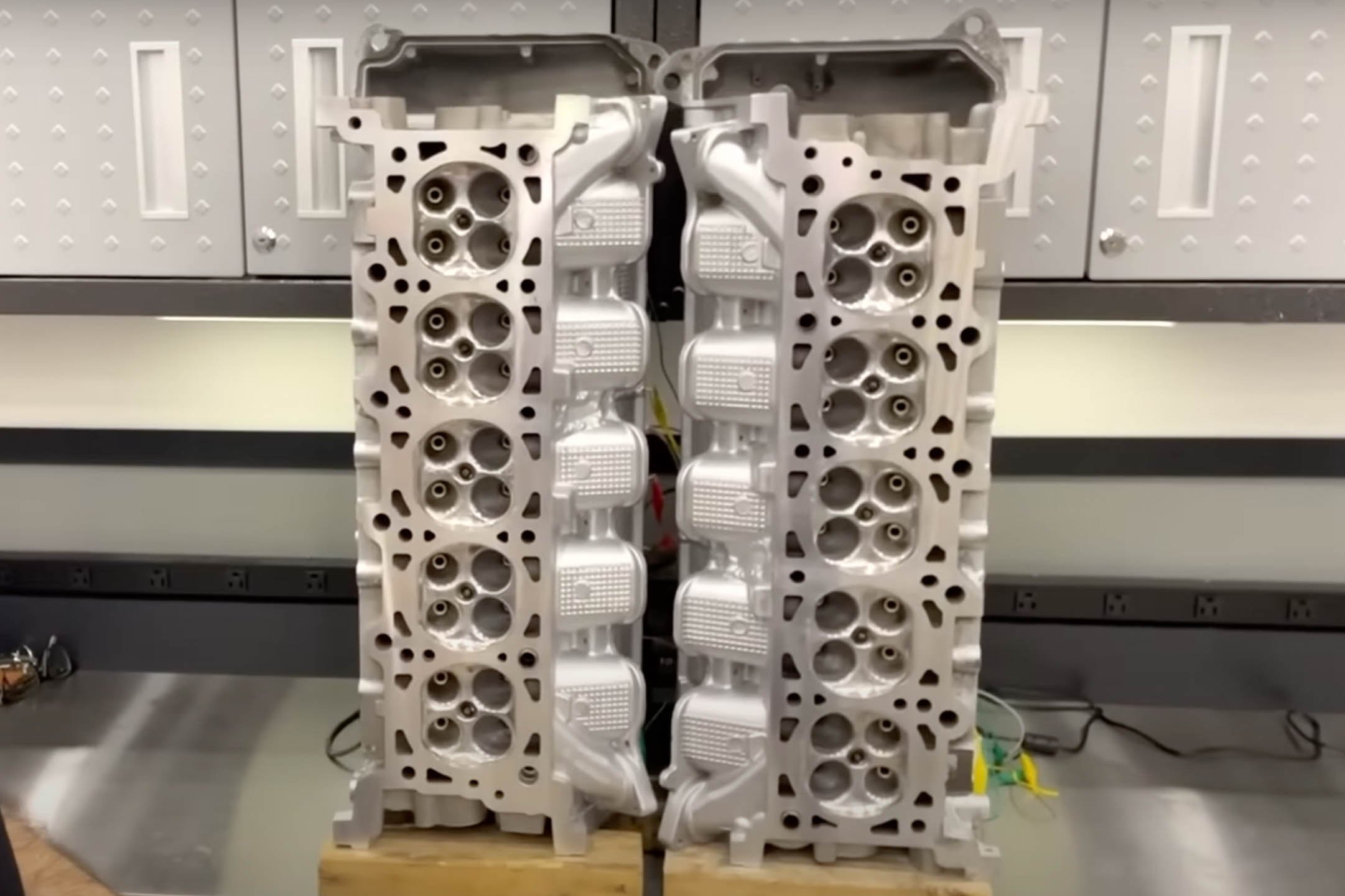

Each Cheetah is outfitted with upgraded shaft bearings and 360-degree thrust bearings. These are an excellent design that gets us excited. The 360-degree thrust bearing is located within the center cartridge and allows a layer of oil to completely encompass the turbine shaft. This is unlike the 75-percent coverage offered by the factory’s 270-degree bearing. Also, since they’re small but mighty, these turbos offer stock-like spooling, which allows you to get your trailer moving sooner, thanks to the Variable Nozzle Technology (VNT).

VNT allows the larger-than-stock turbo to act like a smaller unit upon spool-up, but when you need more power or you’re accelerating harder, it opens up to flow more exhaust at the top end. For you pullers out there, this is also a 2.5-inch work-stock-legal turbocharger.

The demand for emissions-friendly performance parts is at an all-time high, and with the repercussions for tampering with emissions happening so frequently, more and more parts are being developed to accommodate these rules. Unfortunately, truck owners are finding they’re being limited by their turbo size when trying to squeeze out every last ounce of power possible while maintaining their emissions compliance. This is where an upgrade like this is unbelievably beneficial.

Duramax Turbo Upgrade – The Installation

Before we go into the installation of the turbo, know that this isn’t something you can do in a few minutes. These turbochargers are literally buried under pipes, wiring, and other ancillary items. The swap will take some patience and time.

Before we did anything, we wanted to inspect the intake and exhaust system to make sure there wasn’t any debris. Even though we didn’t encounter a serious turbo failure, we want to make sure that we have a clean space and that we weren’t going to contaminate the new goods. Once everything was good to go, off we went.

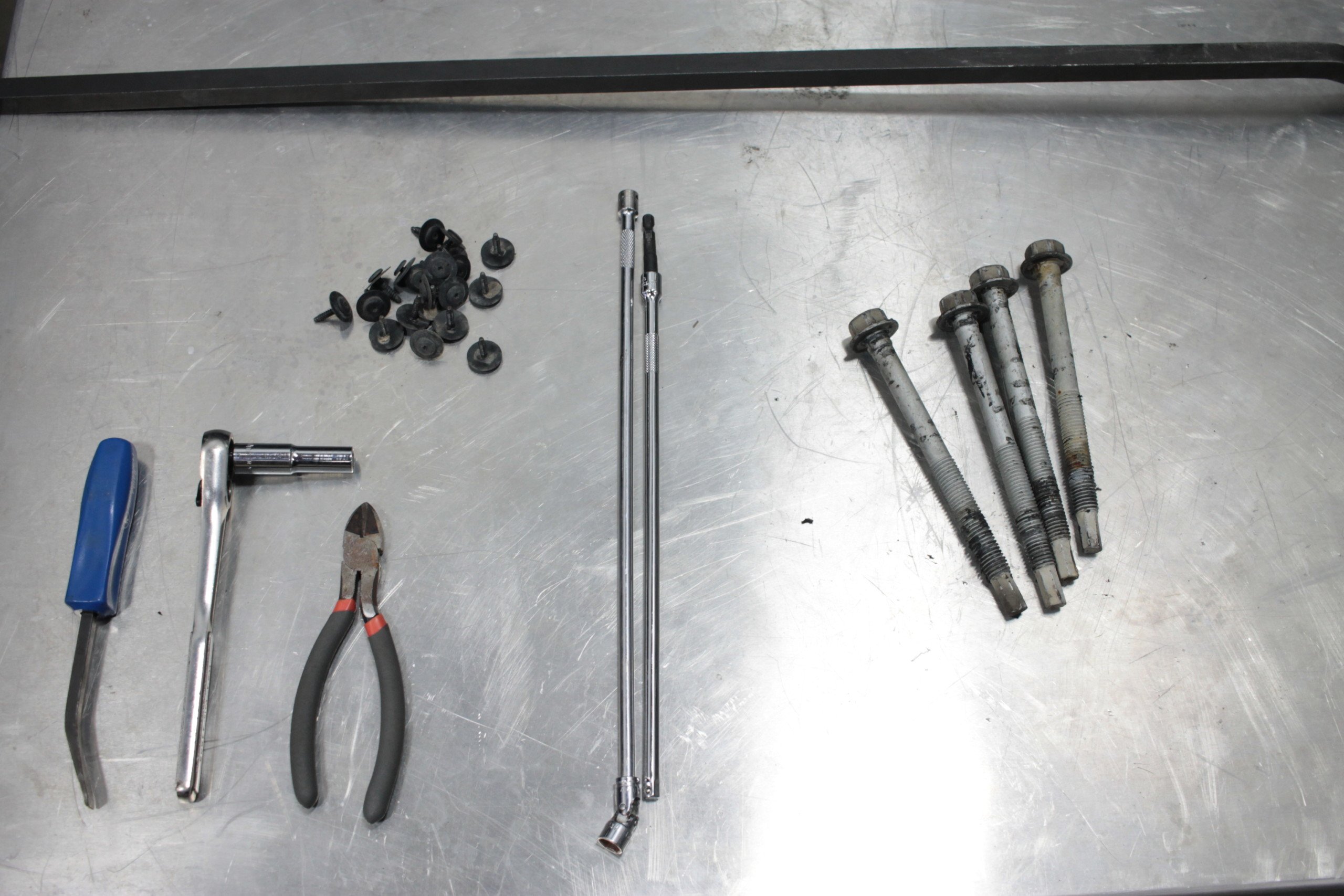

We started removing the items that were either covering or were attached to our old turbo. This included the charge air cooler inlet pipe, EGR manifold cooling feed pipe, turbocharger exhaust pipes, EGR cooler assembly, and upper heat shield. But wait, there’s more. We also needed to disconnect the turbo valve solenoid and sensor connectors, oil feed lines, and the coolant hose. With everything out of the way, all that remained were the turbo mounting bolts. With the turbo completely loose from the truck, it was removed from the engine bay.

Once all of the parts that needed to be swapped were moved over to our new turbo, reassembly began. After a few hours of making sure everything was perfect during the installation, our turbocharger was in, the truck was started, and we checked for any coolant or exhaust leaks — we had none.

As Fleece preached, we ran the truck at a low idle for three minutes to prevent oil starvation damage to the new bearing system, as well as purging any residual contaminants from the bearing housing. We were also instructed to clock the E.O. identification number label in a way in which a smog technician can verify the E.O. number.

The parts that needed to be swapped over to the Cheetah were relocated and our new unit was ready to drop in.

Driving Impressions

Since this is a shop truck, multiple people have the pleasure of driving it. More than one person has witnessed this truck before the upgrade and understands what it was capable of prior to the failure. Now, with this new turbo on board, it is clear they are happy with the result. Everyone who has piloted it since the upgrade has noticed the truck is much more responsive.

When you drop the truck into drive and put your foot on the accelerator, it gets going much quicker than ever. It offers more top-end power, and the sound output is music to their ears. The turbo spools very quickly and then opens up as the RPM and MPH climb. All thanks to that Variable Nozzle Turbo Technology.

We are ecstatic about how this truck turned out after this CARB-legal turbo upgrade. It is now beyond fun to drive and we are excited to put this thing to some serious work for hundreds of thousands of miles to come. If you’re ready to give your truck the upgrades it deserves, check out Fleece Performance.