The bellhousing is the house a clutch lives in, and it needs to be aligned properly with the engine as well as the transmission. The process of indexing the bellhousing to the engine is how you get the correct alignment. In this video from Holley, Jeremy Stoermer shows you how to index a bellhousing the right way.

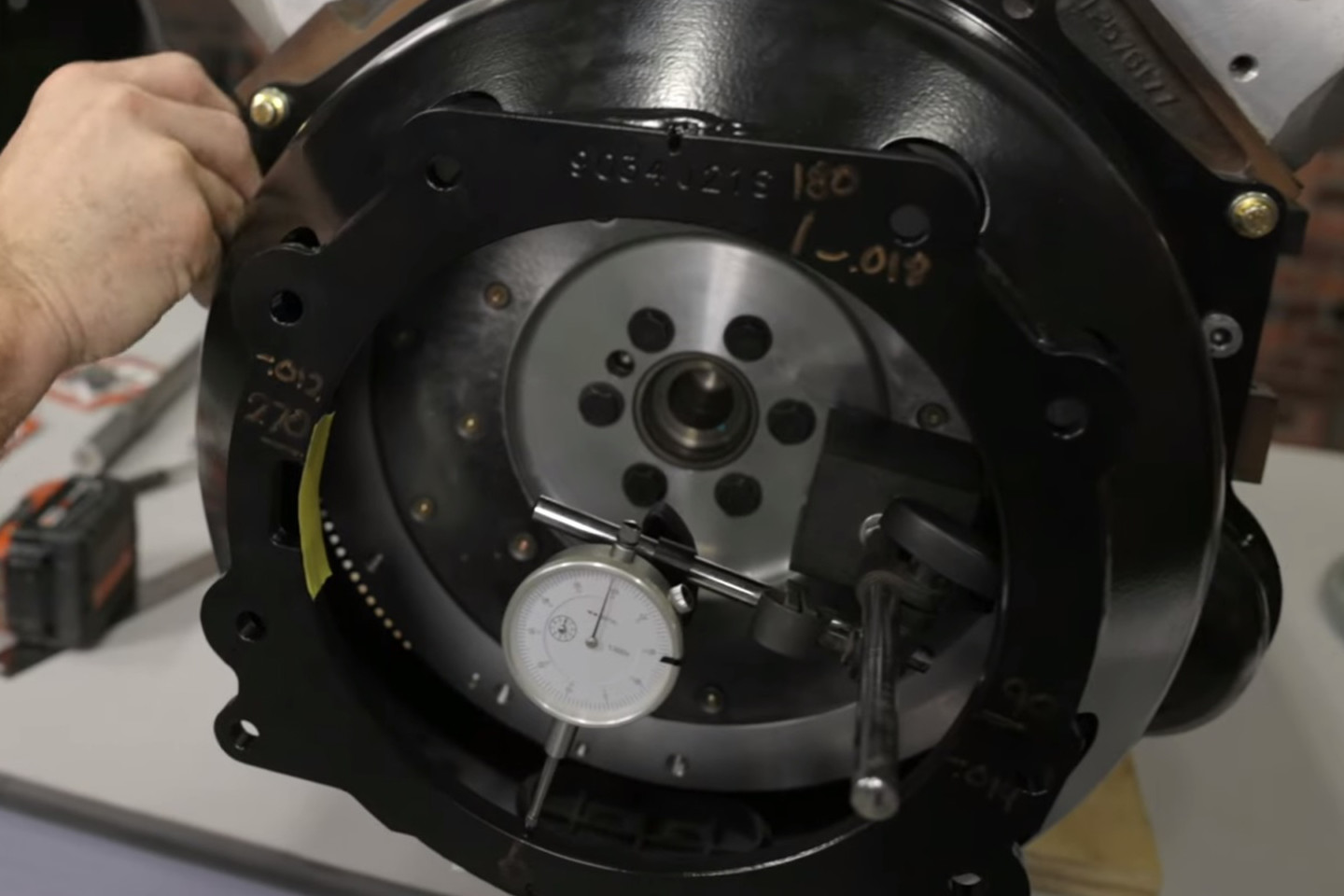

The first thing you’ll need to do is look over the mating surface of the block, transmission, and bellhousing. There could be imperfections on these surfaces that need to be addressed. When the surfaces have been cleaned up, you’ll mount a dial indicator for the indexing process. The dial indicator will then need to be adjusted so the tip is on the center of the bellhousing’s plate. It’s important to make sure the dial indicator is parallel with the bellhousing.

Once you’ve got your dial indicator set up, it’s time to start taking some measurements and making some markings on the bellhousing. When the reading on the dial indicator isn’t increasing anymore and starts to decrease, that’s the spot you’ll need to make your zero mark. After you’ve made your zero mark, you’ll need to make additional marks on the bellhousing every 90-degrees. You’ll record the measurements at each of those marks to calculate your offset. Stoermer goes into great detail in the video on what you’ll do with those measurements.

Your measurements and calculations will reveal the offset direction and amount of offset you’ll need for the bellhousing. There is a certain amount of tolerance you’ll have to take into account when you start looking for the offset dowel pins to mount the bellhousing on. When you’ve selected and installed the correct dowels, you’ll re-index the bellhousing to make sure everything is correct. After you’ve done a final check of everything, just make sure the bellhousing is parallel and you’re all finished.

Make sure you check out the entire video from Holley on how to index a bellhousing. There are plenty of details and tips in the video that will help you index a bellhousing properly on any application.