When it comes to discussing car parts, most enthusiasts tend to focus on the centerstage parts. Things like engines, superchargers, turbos, transmissions, or even rearends. Brake components rarely get mentioned in this conversation. When they do, The sexier parts like powdercoated calipers get the praise. Unfortunately, the quietly efficient brake pad often gets overlooked. As long as the vehicle stops and the pads aren’t making noise, these titans of restraint are often forgotten.

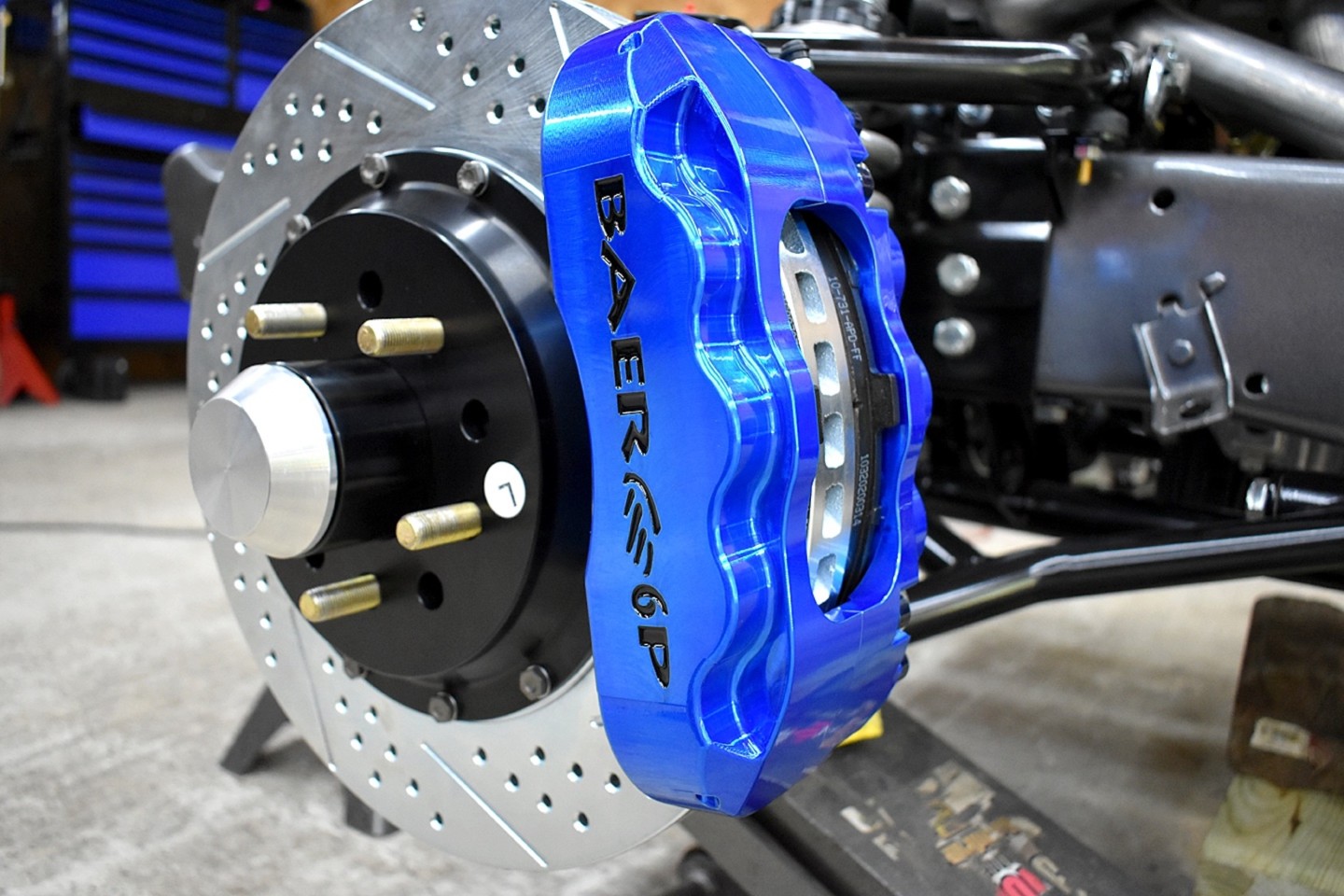

High-performance experts and racers understand the importance of brake pads and the different amalgamation of compounds offered to enthusiasts today. Professional drivers and race teams know a pad with the right friction material will lower lap times. It is most noticeable on oval and street courses. Brake pad compound should always be a huge consideration for any application. To better understand the different types of brake materials and how they work, we got with the experts at Baer Brakes. Depending on your goals, brake pads can make or break your project.

What Brake Pads Do

Many books and hundreds of articles are written each year covering automotive brake systems. The information can be overwhelming and confusing when discussed as a full system. In this article, we wanted to take a deep dive into the humble brake pad. Our goal is to explain the different types of pad compounds and what they do. Most enthusiasts casually order replacement brake pads online or at the local parts store. This is typically done without a thought beyond the price tag.

It is surprising the amount of engineering, research, and development that goes into developing a set of brake pads. Understanding the different characteristics of brake pad types and styles is important to the overall driving experience and safe operation of your vehicle.

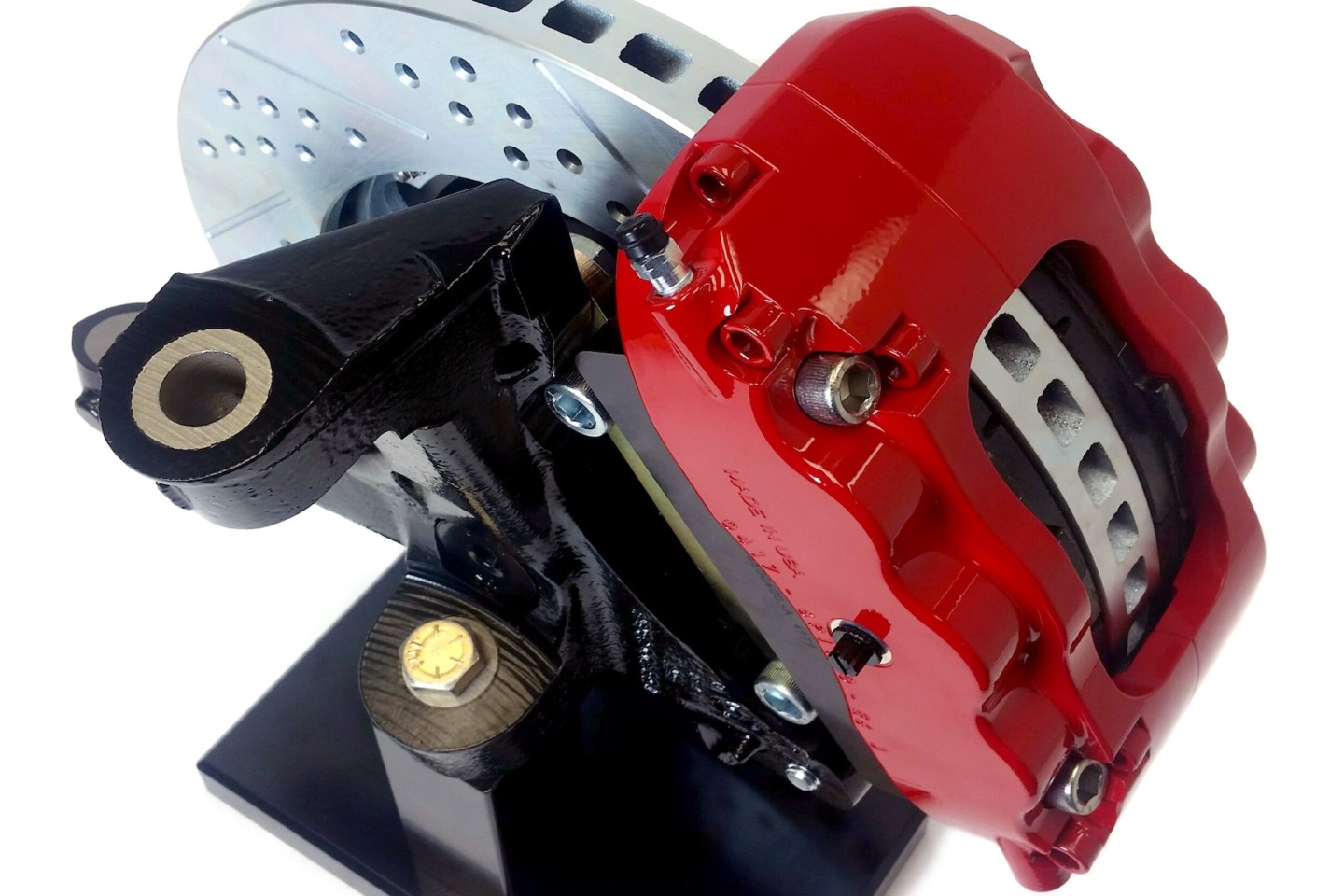

In the simplest of terms, the brake pads clamp the moving rotor disk to bring the car to a stop. If the pads don’t do their job properly, the entire braking process will suffer. There are different driving styles and applications that have different braking requirements. Brake pads with the wrong pad material for an application can lead to poor braking efficiency to worn rotors that need replacement. Brake dads with the right friction compound make a car drive smoother and brake more effectively. Plus, the other brake components will last longer and save money in service and replacement costs.

Avoid Blanket Terms

As a company, Baer Brakes was one of the first to jump into manufacturing brake components strictly for the performance aftermarket. Seeking to focus on engineering design, Baer Brakes has used innovative technology to produce products to raise the expectations of high-performance enthusiasts. In doing so, they have also raised the awareness of stopping power to almost every automotive enthusiast.

“First and foremost, brake pad selection is crucial to the performance of the overall braking system,” explains Rick Elam, Sales Manager of Baer Brakes. “There are a few big points that we want to make about brake pads. The first being that the marketing terms are pretty generic. For example, the term ‘ceramic pads’ doesn’t always equate to a better pad. There are thousands of different versions of ceramic pads out there.”

We took a closer look at brake pad advertising and found that Elam was correct. Using very plain and generic terms, almost every parts store offered brake pads in three basic categories: Organic pads, semi-metallic pads, or ceramic pads. Suddenly, it made sense to us. If you went into a parts store to order a set of brake pads, the store was likely going to offer you a “good, better, or best” selection. In generic terms, organic pads would be good, semi-metallic would be better, and ceramic would represent best. For most casual automotive consumers, the are blanket terms that are widely accepted. Not so fast if you are a detail-minded enthusiast!

More Than One Recipe

Elam points out the compounds that makeup friction materials are formulated from hundreds of different constituents that are engineered to achieve specific and desired characteristics. There’s no “one size fits all” combination of components that make up a great organic friction pad or a great semi-metallic brake pad. There’s more than one recipe and more than one outcome.

“In brake pads, there can be up to 300 different components used to make a compound,” Elam explains. “Changing the quantities of these ingredients can have a dramatic effect on the performance and braking characteristics of the pad.”

“The type of driving you do vastly changes your brake pad needs,” Elam explained. “A daily driver is going to use a much less abrasive style pad compared to a race pad. Let’s say you want to daily drive with a race pad. During testing, we’ve seen that the rotors will wear up to three times faster than with their daily-driver-style brake pad counterparts.

With so many different applications, brakes need to be customizable for the user and the intended use. Brake pads are one of the easiest and most surefire ways to contribute to the feel of a car’s braking system.

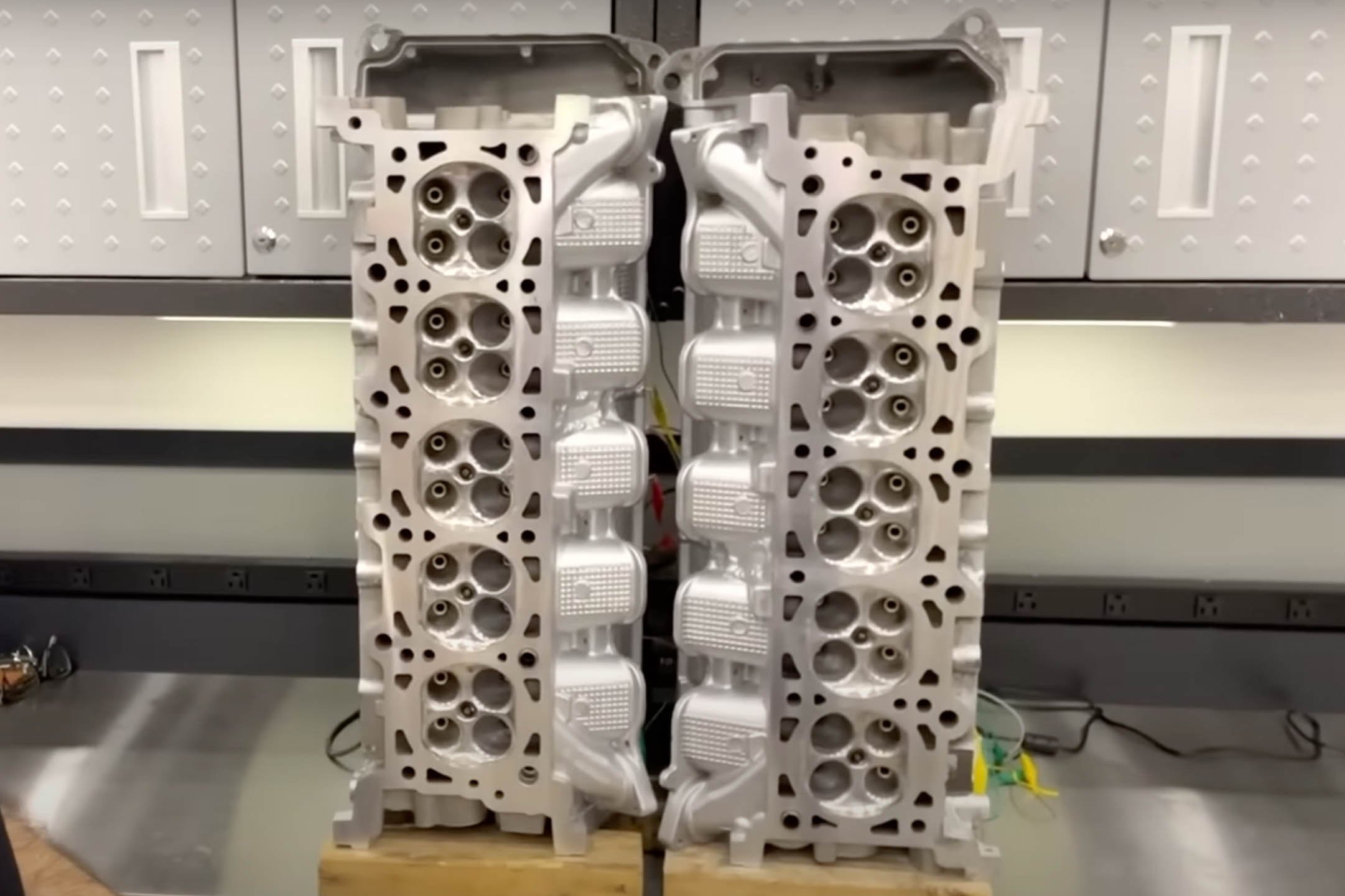

The Engineering Involved

By this point, we gained an understanding that manufacturers create pad compounds for specific applications based on specific characteristics. Baer’s Tim King explained to us that pads designed for common street use are built to be as quiet and dust-free as possible. The trade-off with these characteristics is a small sacrifice in friction level.

Conversely, pads designed for road racing will have a compound with a higher coefficient of friction and higher heat threshold where noise and dust are not important. “Drag race brake pads are engineered to operate with very little heat at the time of use but still provide tremendous stopping power,” said King.

“Drag racing brakes are the hardest to design,” Elam adds. “They need to be compact and lightweight. The pads themselves are a challenge though because they are expected to perform when cold. A good drag pad is going to work when cold and have high friction to slow the car down. The downside is that the brake pads will be noisy and create lots of brake dust. Generally speaking, people think if a brake system is creating lots of dust and is noisy then something is wrong. That’s not the case. A performance racing brake pad will create lots of dust and be a noisy pad, but will stop amazing when used properly.”

Baer relies on a strict engineering process to deliver performance. “We look to brake pad companies to engineer and select different compounds,” Elam explains. “What we do is tell them what we want the brake pad to do and they will create a brake pad and provide a dyno sheet to document its performance. If the pads meet our specifications, then we take the pads and do real-world testing with them.”

Driver’s Preference

“Most of our calipers utilize standard pad shapes. This means that there are tons of options out there, and drivers can easily try any number of readily available brake pad compounds to achieve the desired result. As we mentioned before, brakes and brakes pads are super user dependent on what each individual wants. Just because one racer has a certain pad and that works well for him doesn’t mean that another racer will like that pad and it performs as well with them.” Every racer is going to like a different feel when it comes to stopping. Fortunately, there are as many different types of brake pads as there are driver’s preferences. The options are nearly limitless.

“Brake pad selection is very much a personal choice.” Elam continues, “One person might like a ceramic pad while another might like a semi-metallic. Again, one isn’t better than another. For example, one driver might like to really stab the brakes at the last possible second, while another might like to slowly apply the brakes. These techniques require two completely different styles of brake pads. Customers can, and often do combine different compound brake pads – one for the front and one for the rear. The rear pads obviously don’t see as much use as the front, so they might run a race in the front and a street in the back. However, if they adjust their bias, they can get more use out of the rear. Driving this point home, it’s 100-percent user preference more than anything else.”

Pad Selection

According to Elam, “there isn’t one style of pad that’s better than another. There are too many variables in the construction of the brake pads, driving style, intended use, and other factors to say that one style of construction is better than another.”

No matter if you have a daily driver, a weekend street/strip warrior, or a purpose-built race car, the braking system is extremely important and no aspect should be overlooked. When it comes time to replace the brake pads or change the driving characteristics by tuning with brake pads, do your homework. For more information on brake system components or brake pads in general, check with the professionals online at Baer Brakes or call 602-233-1411.