Muscle cars were meant to be driven, not stored away in a collection and never enjoyed. There, I said it. I am certain I will be getting more than a few scathing emails about why certain cars should not be driven, but that’s okay. But, if you are of the same mindset and really want to improve the driving experience you get with your classic hot, you will probably want to keep reading as we check out a few rides with suspension upgrades that handle like engineers never imagined thanks to Total Cost Involved (TCI).

Typically, auto journalists write about building horsepower, but this time, I think we need to discuss creating a way to make the ultimate driving/handling machine. When our classic Chevy’s were new, the suspensions underneath were adequate for the times. Okay, if not worn out, those underpinnings can still be thought of as adequate, but nobody wants “adequate” when talking about their classic ride. If that were the case, the performance aftermarket would not be a multi-billion-dollar business.

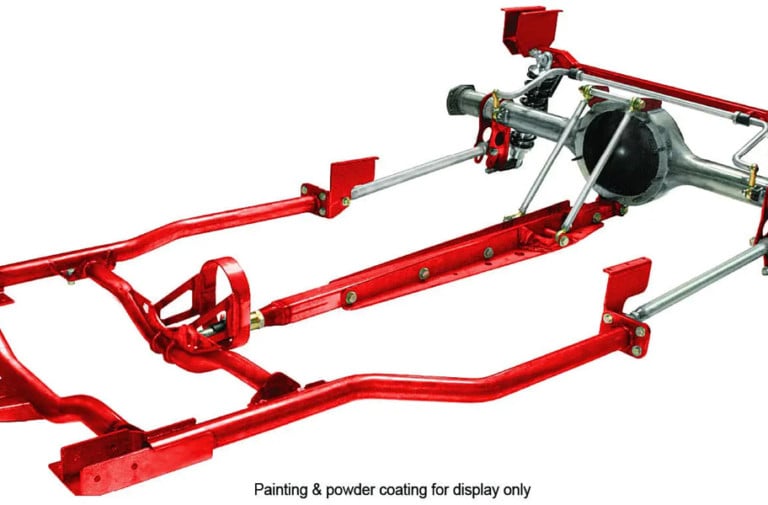

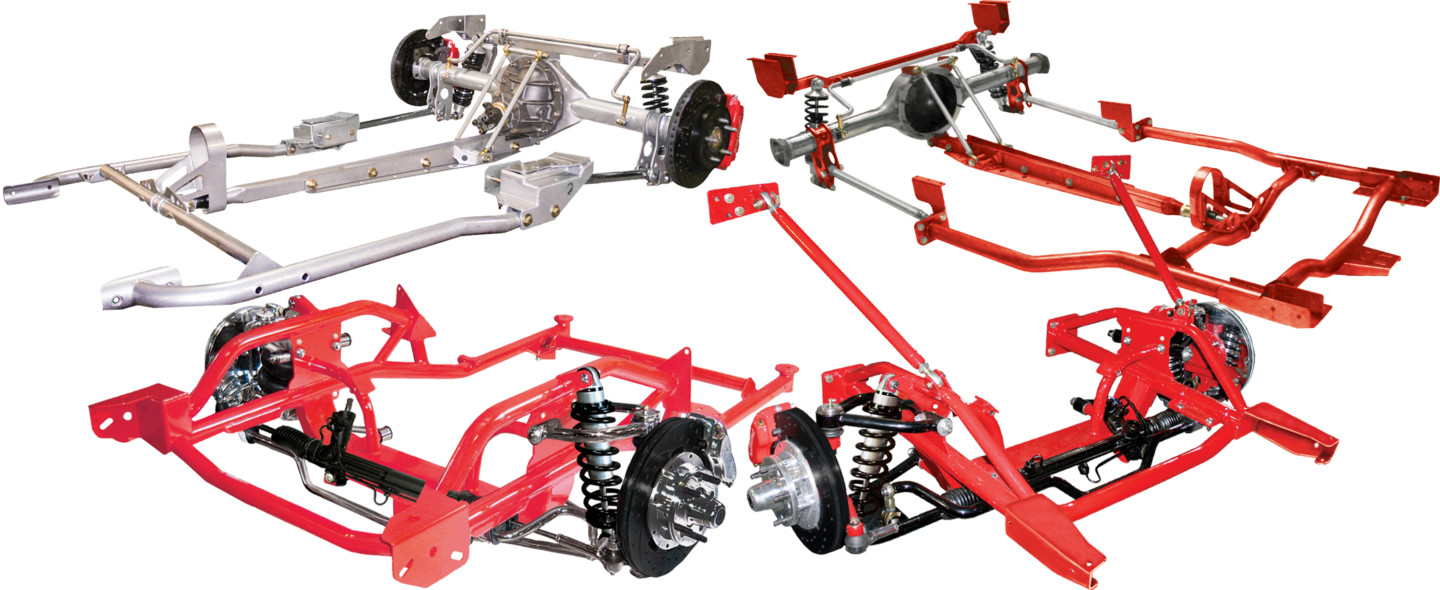

A four-link (left) is primarily designed for street/strip use. It provides better geometry for straight-line performance. They will typically have better axle control and available anti-squat, which helps plant the tires. Adversely, braking will suffer if the anti-squat value is high. There are some drawbacks like suspension bind during articulation. Some of this can be offset by using proper articulating joints, like the Ridetech R-joint. A torque arm suspension (right) is primarily designed for street and autocross. It provides better geometry for cornering. The torque arm uses a telescoping slider at the front that allows full travel and articulation without any binding. The torque arm will plant the tires fairly well in a straight line, but the anti-squat values just won’t be as high as with a four-link.

“Every business has a beginning story. What prompted the need for TCI to be created, was Ed Moss, our founder and president, wanted to provide customers everything they needed to complete their build,” says Jason Wilcox of TCI. “In the mid-‘70s, when he started Total Cost Involved, there wasn’t much availability of complete suspension packages or chassis. He sought out to live up to the name Total Cost Involved.”

It All Begins With A Foundation

When you build or modify your hot rod, the process of part selection can involve a myriad of individual choices. The style in which you choose to create your ride can be the culmination of day-two-appearing parts, high-tech amenities, or even a combination somewhere in between. But when it comes to the chassis and suspension upgrades though, we are talking about a definitive starting point that can give your ride its most characteristic appearance for all other pieces and parts to follow.

I want you to keep one thing in mind as you read this, every great hot rod begins with a solid foundation. What I mean is, starting from the ground up with components that are quality made and designed to enhance your vehicle is the key to success. To get that point across, I thought it prudent to not ask TCI why they feel its suspension upgrades are required material for a great hot rod, but rather, to speak to a couple of independent car owners that truly understand what it means to enjoy — and push the limits — of their rides. Efrain Diaz and Kevin Beach are two regulars on the NMCA autocross circuit, and both are highly regarded as Champion material. It takes a person with driving skills and a car that is designed to handle at its best to accomplish what these guys do each time they attack the autocross course.

Corner-Carving Camaro

Efrain purchased his ’69 Camaro at the Pomona Swap Meet almost 20 years ago. Back then, the car was, in his words, “a big, old, rolling turd.” The car was a true RS-optioned car, but it was in seriously rough condition.

Originally, he planned to restore it, but those ideas took a drastic turn when he attended a Goodguys’ meet and saw Mary Pozzi wheel her Camaro around the autocross course. He soon realized that having a car that handles would be much more fun than a restored car that sits in the garage.

Efrain Diaz’s car might look like a thoroughbred race car, but with the A/C turned on, it’s a cool cruiser as well.

“I’ve owned it for about 19 years now, and it’s gone through many changes,” Efrain quips. “In fact, probably the only things that haven’t changed are the paint color and that it’s an RS.” But the initial building of his cornering star did not come easy — or overnight.

According to Efrain, “I’ve had at least four different suspensions under this car. I started with typical bolt-on stuff, but it wasn’t until I got the bug to do autocross and road racing when things got serious. Before installing the TCI suspension upgrades, the underpinnings were something I cobbled together from other people’s cast-off parts. I found some success with the car, but it wasn’t until I caught the attention of TCI’s owner, Sal, that things really got serious. We talked about my plans for the car and evaluated my options. Then I pulled the trigger on a complete system that was light, well-engineered, and proven. In my first year of running the TCI Pro Touring suspension (with a torque arm), I won the vintage-class trophy at the Optima Ultimate Street Car Invitational in Vegas.”

Handling is one thing, but most of us like to install our upgrades ourselves. So, I thought it prudent to hear what Efrain thought about the task of doing his suspension upgrades. “Installing the suspension was surprisingly straightforward as it is a true bolt-in system. All major mounting points that retain the original subframe and rear axle are incorporated into the design. The most difficult part was getting the car high enough to pull the old stuff out. This was all done in my garage. Having a friend over helps a ton. I really encountered no real hiccups while doing the swap. Just changes to things I previously modified for my old suspension. If I had the opportunity to do this all over, I would not have wasted time trying to cobble things up myself and just gone with a matched front and rear suspension. But it’s all part of hot rodding: learn, adapt, improve, and go faster.”

One rumor that has spread like wildfire is that suspension upgrades like this will affect the street manners/ride quality of the car. Well, duh, that’s what it is designed to do. However, some of those rumors began with enthusiasts who, unfortunately, did not get parts designed for the actual use they are encountering. In other words, they probably bought a full-boogey race-oriented setup for their driver hot rod. It happens, we all want to have the baddest and best on our cars, but sometimes, that’s not the best option. That’s why being honest about what you really want to do with your car when you decide on a new suspension is paramount. In fact, since Efrain does drive his first-gen on the street, I asked about the ride quality.

In my first year of running the TCI Pro Touring suspension (with a torque arm), I won the vintage class trophy at the Optima Ultimate Street Car Invitational in Vegas – Efrain Diaz

“The car has great street manners,” Efrain affirms. “The ride can be adjusted to be stiff or Cadillac smooth, simply by adjusting the coilovers. The suspension provides modern geometry, which gives it the ability to handle as good or better than most modern sports cars. It’s driven to work a couple of times a week and driven to events within a four-hour drive. It even has A/C.”

Avoiding Cones With The Beach Boys

Harrison and Kevin Beach might not be able to sing a ‘60s-based California seaside tune — or maybe they can, who are we to say — but the duo definitely knows how to make a station wagon peg the cool meter. The Beach men purchased this multi-family-member cruiser before Harrison was able to drive. When they acquired it, the Nova wagon was nothing close to what it is today. Back then it was a 400 series that had been the recipient of a 350 small-block and a 700R4 transmission. The wagon was sporting a Mustang II front clip and a TCI four-link-suspended rear. Since then, It has received some serious suspension upgrades.

Anyone that says wagons are for hauling the family, is right. However, this wagon can do it quicker than most muscle cars.

“We upgraded, using TCI suspension parts because this car is for my son,” says Kevin Harrison. “Harrison was 14 years old when we bought it, and I needed something that was safe, reliable, and well supported. I liked the fact that TCI products are made in the USA with U.S. steel. Other pluses were the inclusion of a complete hardware kit, inner fenders, and subframe connectors. The dual warranty is icing on the cake.”

It’s driven to every cruise, show, and local race. The only time it’s trailered is for NorCal and out-of-state events. – Kevin Beach

Speaking of the dual warranty, all TCI Engineering products come with a 6-Year/60,000-mile warranty on wear and tear items like bushings, coilovers, and ball joints. Any items built in-house by TCI, such as link bars, control arms, spindles, crossmembers, etc., come with a lifetime warranty. That is confidence in a product.

Kevin continued by saying, “The car needed to be tough, in order to survive a teenage learning curve. It sees thousands of street miles per year. It’s driven to every cruise, show, and local race. The only time it’s trailered is for NorCal and out-of-state events.”

As far as ride compliance, Kevin’s opinion mimics Efrain’s, “The ride can be anything the driver wants. We started with a compliant spring rate and shock tune, and the ride quality is excellent for something that handles so sharply. As my son moved into racing autocross, we increased the spring rate and added rebound damping. At the end of each event, we simply open the rebound and return the car to a street ride.”

If you would like to upgrade your ride but do not want to spring for a complete chassis in one fell swoop, you can upgrade like the Beach’s did, one section at a time. When we asked Kevin about the difficulty of installing the TCI front suspension, subframes, and rear torque arm suspension, he added, “The installs were a fantastic experience. My whole career has been in the auto industry, but I’ve never done anything like this. We followed the instructions and had the front clip in over the course of a weekend. I was shocked at how easy it was and that we didn’t need to make trips to the hardware store. Everything lined up well and the job was done.”

Kevin continues, “the rear Torque Arm and Currie 9-inch rear was done a few years later, as was adding the mini tubs. We removed the previously installed four-link to install the torque arm suspension. It was easy, with all the components lining up per the instructions. Once the car was back on the road, the handling quality was instantly apparent. There was no loss of straight-line grip, but the lateral grip was greatly improved. We’ve had the TCI suspension in the car for seven years now and the car continues to be awesome.”

Why Total Cost Involved

I know many enthusiasts would really like to upgrade their hot rod’s suspension, but still have reservations about the purchase. I asked Jason what he would say to an enthusiast who is on the fence about purchasing TCI suspension upgrades. “We are and always have been a family-run business,” he emphatically states. “Ed, our founder, even at 77 years of age, is here hustling five days a week. We have one guy that has been here since the ‘70s, and we joke that he’s been here longer than Ed. When it comes to quality, all TCI parts are made in America. We offer the best warranty in the business because we have confidence in our product and raw material suppliers. We also have the utmost confidence in our suppliers like Moog, Currie, and Wilwood, so we offer warranties on those products as well. When you purchase a product from TCI you become part of our family. #TeamTCI.”