Second-generation F-bodies have so much to offer. These cars look fast, even when sitting still. The car’s performance potential also makes it a favorite for pro-touring competition on the autocross or the open track. That is exactly why Derek Dean chose this 1971 Chevy Camaro as the foundation for his corner-carving endeavors. To do that, he’s implementing a Speedtech Performance Grand Touring kit designed for GM’s second-gen, F-body suspension.

The Camaro was a solid foundation but the entire suspension will be updated with a complete Speedtech Grand Touring chassis.

GM’s 1970 through 1981 F-body was intended for performance driving. But, over time, better suspensions were created and the second-gen Camaro and Firebird’s limitations became undeniable. Thankfully though, companies such as Speedtech Performance have studied the car’s shortcomings and created components that heighten the car’s performance by integrating them with today’s modern technology.

A Complete Grand Touring F-Body Suspension

The Speedtech Grand Touring F-body suspension is a complete system designed to upgrade your car’s handling while still utilizing the car’s factory subframe assembly. It goes without saying, caution is necessary when swapping out the factory components with the Speedtech kit as the coil springs are under a lot of force.

Unlike the company’s Street Fighter suspension system, the Grand Touring package is designed for true pro-touring enthusiasts and does require a few modifications. For the front suspension, the kit requires modifying the frame to add the upper coilover shock mount and make room for the coilover shock. After welding in the Chicane Bracket as the upper coilover mount, the system will then have all the benefits of a true coilover suspension.

The Speedtech Chicane Bracket is welded in place of the upper shock mount and allows for a gain in shock travel over a hybrid type of coilover system.

Beyond the frame modification, the Speedtech team has kept this upgrade as bolt-in as possible. The kit gives all the adjustability of coilover shocks, and those hefty tubular control arms have been engineered to deliver the best geometry possible for performance driving. In the rear, the Speedtech Grand Touring suspension offers a huge improvement thanks to its torque arm-designed rear suspension.

Pro Touring A Second-Gen Camaro

The heart of pro touring is fitting the largest tire possible under the bodywork of any vehicle. The Grand Touring suspension does a good job of making the necessary room for those big tires, but the body of Derek’s Camaro needed a little more work. Once Derek got the Camaro home, he began by tearing it down to the bare elements. From there, it was obvious there was some rust work to be completed, as well as some clearance issues to be addressed before the rebuild could begin.

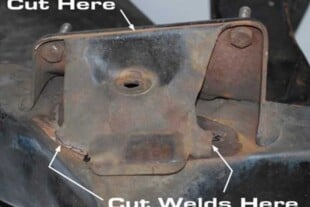

The upper shock mount needed to be removed and the spring pocket in the frame opened up so the coilover could clear the frame. Then, after trial fitting, the Chicane mount is welded to the frame.

The rear of the Camaro had seen better days and a full complement of sheetmetal was ordered to bring everything back into better-than-new condition. With the body repairs complete, Derek began smoothing and preparing the body and the modified front subframe for painting and undercoating. With everything looking like a million bucks, he began by bolting the F-body suspension in place.

Building A Grand Touring Front Suspension

Proper setup when building a vehicle’s suspension is vital for optimum performance. The Speedtech Grand Touring F-body suspension allows for much more adjustability to get the suspension settings to more optimal measurements. The Speedtech components allow much more caster to be added to the suspension. Whereas the factory setting was only 1/2 degree of positive caster, the new suspension can be adjusted to the recommended four degrees (street setting) and up to six degrees for aggressive track driving.

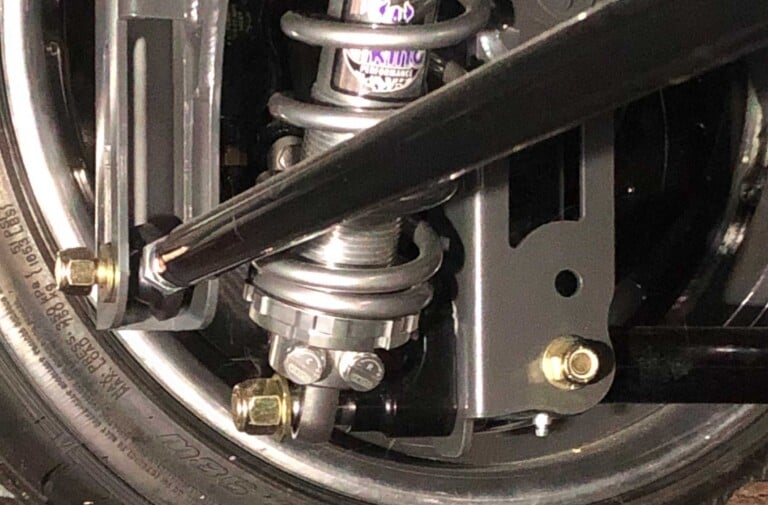

After painting, Derek installed the control arms, coilover shocks, and spindles. Note the billet, bolt-on steering arms. The Speedtech Performance steering arms move the outer tie rod end joint outboard, which improves Ackermann. Also, the height of the outer tie rod joint was modified from the O.E. location to help bumpsteer.

Derek upgraded to Speedtech’s forged spindles for several reasons. The spindles are forged from exceptionally strong 7075 T73 aluminum and are machined to use a maintenance-free, C7 Corvette hub assembly. The spindles also have a revised, bolt-on steering arm for improved bumpsteer and the taller spindle enhances negative camber gain under suspension load. There is also a 1-inch drop incorporated into the spindles for that lowered look.

Installation of the F-body’s suspension began with the lower control arms, and then the coilover shocks. From there, the upper control arms can be bolted in place. Derek then added the bolt-on steering arms to the spindles and mounted the spindles to the control arms.

A proper steering assembly is vital if you’re wanting to have control of a vehicle throughout a turn. The Speedtech kit not only allows for control, but it alters the geometry slightly for even better control. The kit comes with a steering idler arm relocation mount that adjusts the position of the idler arm to better match the arc of the Pitman arm on the steering box. Speaking of steering boxes, Derek also opted for a 12:1 ratio Sweet Manufacturing steering box to help him saw around apexes and cones.

Adding A Torque Arm To The F-body Suspension

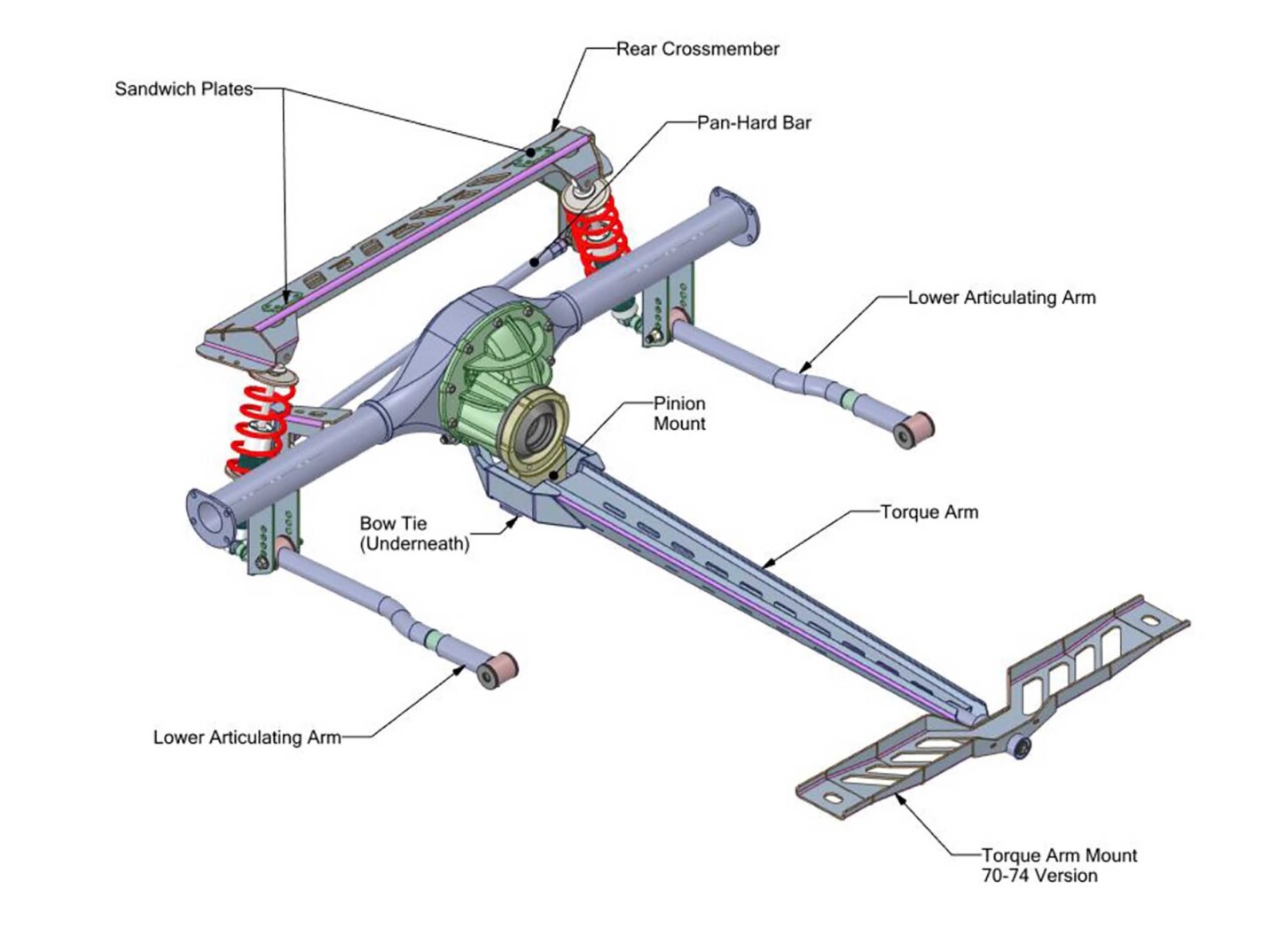

The Speedtech Torque Arm rear suspension system not only rids your F-body of the slop and flop of the factory leaf springs, but it also transfers torque directly to the center of the vehicle under acceleration and braking. The Torque Arm floats in a receiver near the center of the chassis, transferring acceleration and braking forces into the center of the car, which greatly reduces body pitch.

The rear suspension utilizes this torque arm to help limit the rotation of the differential and direct the forces of accelerating and decelerating toward the center of the vehicle.

The Speedtech torque arm assembly is not intrusive to the trunk or rear seat area and requires only a small amount of welding under the car. The rear section of Derek’s Camaro is finished as nicely as the front, and Derek welded the upper crossmember to his Camaro before painting and undercoating the area.

The upper coilover mount was welded onto the Camaro’s frame before paint and undercoating. The front of the torque arm will go into the round opening at the front of the driveshaft tunnel.

Also, Derek purchased Speedtech’s rear axle housing that was already set up for the torque arm assembly. If you use your current rear axle housing rather than ordering a new Speedtech-prepped axle housing, you will need to remove the existing leaf spring axle pad mounts and have the torque arm’s rear axle brackets welded on. A guide for the bracket location is included in the instructions. The Speedtech torque arm assembly is engineered to work with GM 10- and 12-bolt housings, and Ford-style 9-inch housings.

From there, the rest of the installation is a bolt-in process. The torque arm is bolted to the differential and then slid into the front crossmember which ties it into the front subframe. Both trailing arms position the rearend housing. The proprietary Articu-Link trailing arms connect the rear housing to the vehicle. The Articu-Link rotates on its own center, which reduces bind so that only the coil-over shock is providing resistance to the movement of the axle relative to the body. The coilover shocks are then free to set the vehicle’s ride height and control movement without the effects of binding.

The Grand Touring suspension allows for much more adjustability than the original suspension. The Panhard bar maintains the side-to-side movement at a minimum and can be adjusted to change the rear roll center and roll axis. The height of the trailing arms can be adjusted at the axle and can be used to help tune for improved rear traction.

Once installed, tuning the vehicle’s roll center and loading of the chassis during acceleration and deceleration can be done by adjusting the pinion angle, trailing arm height on the axle, and Panhard bar. The torque arm suspension is a great way to improve performance and handling with no axle wrap or wheel hop while giving you a more confident and smoother ride. The addition of a fully adjustable ride height, roll center, anti-squat, and shock valving means Derek will be able to customize the look and feel of his F-body to his exact driving preferences and course conditions.

The Grand Touring suspension kit includes tubular front control arms for the front, the torque arm assembly for the rear, and coilover shocks all around.

Stay Tuned For More On This Pro Touring 1971 Chevy Camaro!

We can already see that Derek’s Camaro is going to be quite the performer and the work so far just shows his abilities and talent. We can’t wait to see how this car looks (and performs) once he’s done working his magic with wrenches and body tools. Rest assured we’ll be covering more on Derek’s wild pro-touring 1971 Chevy Camaro. Keep in mind, these upgrades will improve any 1970-1981 GM F-body suspension. If you want to turn your second-gen into a corner-carving monster, give the folks at Speedtech Performance a call at (435) 628-4300. Then, your biggest issue may be struggling to find room for all the trophies and awards.