Is it really possible to add more than 100hp to your LS motor with a cam swap? The answer is obviously yes, or this would be one very short and disappointing tech story. Before we get to the test, we first need to understand why it might be possible to get such big gains for a simple cam swap.

Naturally, the presence of forced induction plays a major part, but LS engines have a lot more going for them than just their propensity to swallow copious amounts of positive pressure. In terms of responsiveness to changes in cam timing, the GM engineers set the stage with the LS platform. What do we mean by this? Well, any LS motor has basically everything else it needs to provide premium performance, except the cam.

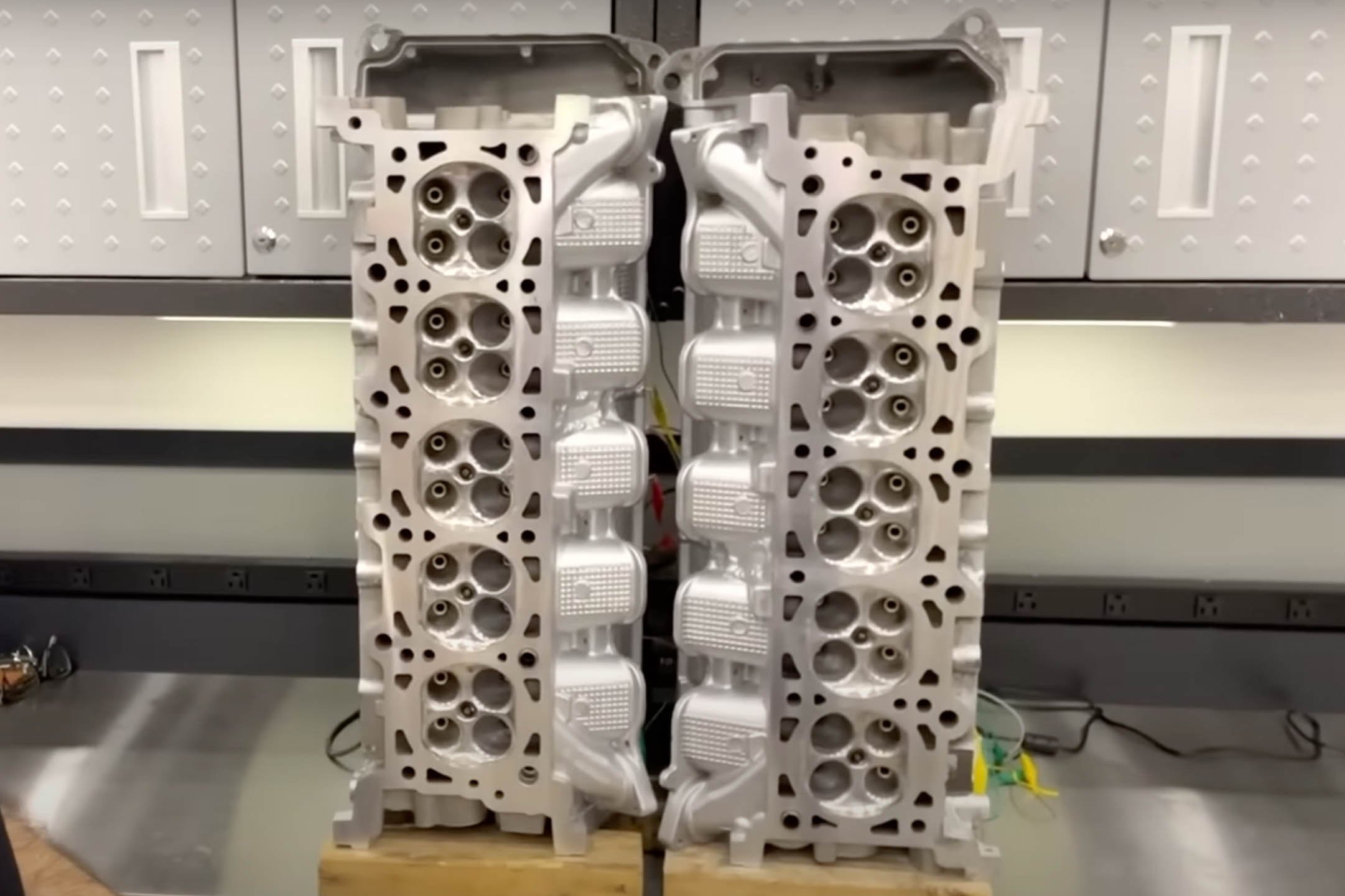

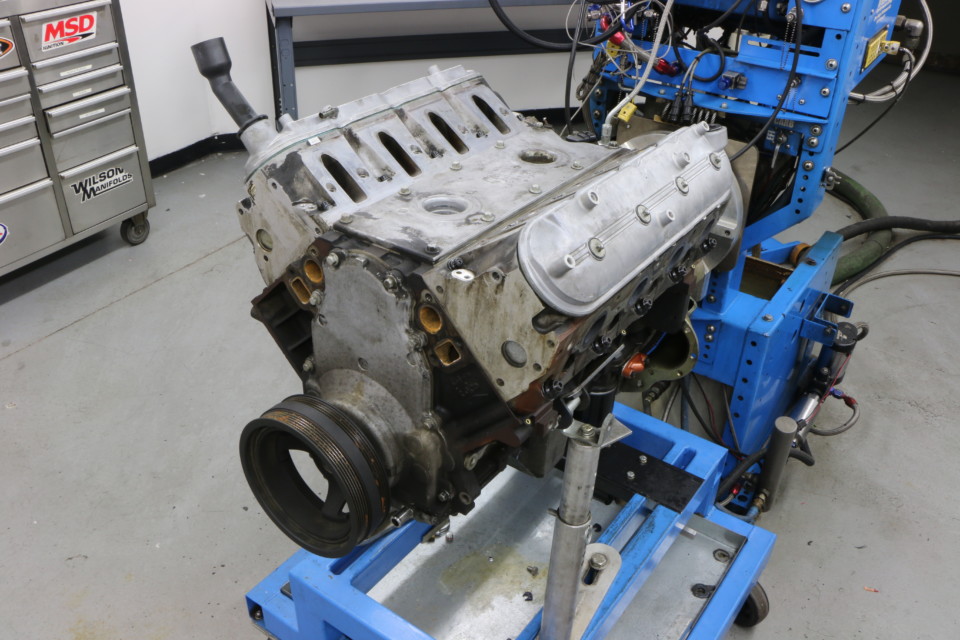

Our test motor is one of the most common LS engines found in junkyards. The junkyard 5.3L retained all of its factory components for our test, including the short block and factory 706 heads. Prior to testing, the motor received increased ring gap, new head gaskets, and ARP head studs. Although, none of this was mandatory at this power and boost level. We were prepping it for future testing.

No single component can make a motor, but almost any single component can break one. All it takes to ruin an otherwise perfectly good performance motor is one wrong part. Install the wrong intake, cylinder heads, or (in our case) camshaft, and you’ll have less than ideal results. When you cure the one missing component, the results can be amazing. The LS has plenty of displacement, head flow, and a more than adequate intake manifold. The only thing missing in the otherwise-perfect combination is adequate cam timing!

Knowing we had a cam swap coming up, we replaced the factory truck springs with a set of 26918 springs from COMP Cams.

So, just how much power did GM leave on the table when designing the cams for the various LS applications? In all honesty, the design criteria for the engineers was never to maximize power, but believe me, they certainly could. The factory offerings were (by design) mild compared to what was ultimately possible.

But, even the factory cams differed in their performance ability. Low-man on the power totem pole was obviously the cam used in our 5.3L LM7 (shared with the 4.8L LR4 and early 6.0L LQ4). Designed for low-rpm truck applications, the LM7 cam offered a .466/.457 lift split, a 190/191-degree duration split and 116-degree lobe separation angle (LSA).

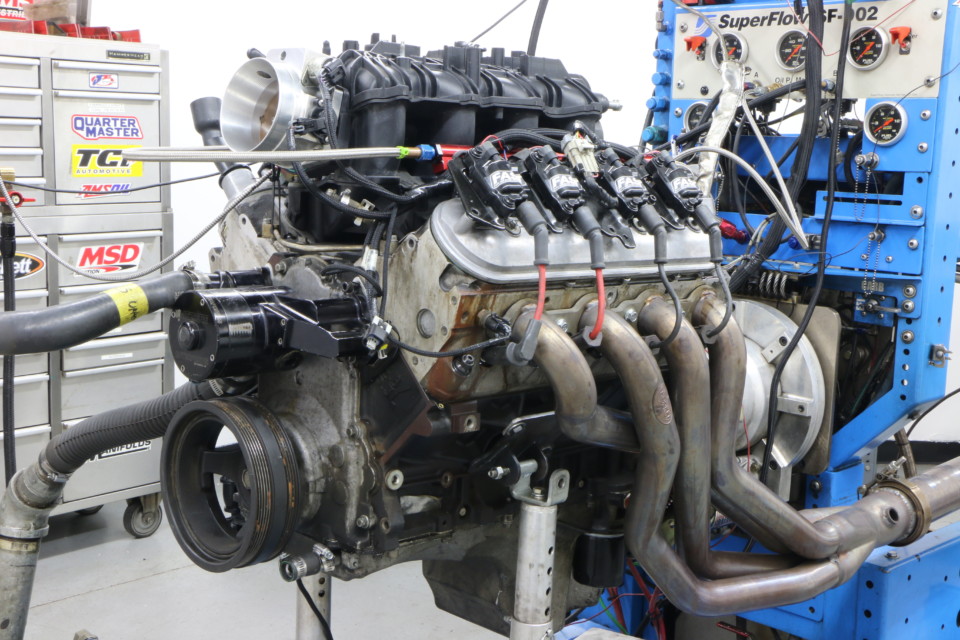

We selected a set of FAST 89-pound injectors and FAST fuel rail for the TBSS intake to supply the necessary fuel for our turbo motor .

Let’s put this mild cam timing into perspective. The LS9 – the most powerful of the factory LS cams – offered a .558/.562 lift split, a 211/230-degree lsa, and 122.5-degree lsa. Though it was designed for a supercharged application, the LS9 cam was all but identical to the 427-inch LS7 cam. The difference being the LS7 cam offered more lift due to the 1.8:1 ratio factory LS7 rockers. The rest of the production cams (LS1-LS6) fell somewhere between these two extremes. Given the mild factory cam timing, it should actually come as no surprise that cam swaps on a naturally aspirated 5.3L can yield 40, 50, or even 60-extra horsepower.

The gains offered by cam swaps on the LS have been well documented. But, what allows a gain of 40-60hp on a naturally aspirated LS to exceed 100hp on a boosted one? The answer is in the multiplier effect. A naturally aspirated engine is already running under an atmospheric pressure of 14.7 psi. So, all we have to do to double the power output of say, a 300hp engine, is double the pressure, right? If we apply 14.7 psi of boost to the same 300hp naturally aspirated engine, we can see 600hp.

Dialing in the air/fuel and timing values was a Holley HP engine management system. The A/F and timing curves were kept constant for the two cams.

Why we don’t always see that much power is often a function of things like the tune, charge cooling, and turbo efficiency, but rest assured, it is possible. In fact, it is possible to exceed this simple formula with sufficient charge cooling (by using things like ice water). The real exciting part is when we increase the power output of our naturally aspirated motor.

Suppose we add a cam to our 300hp test motor and increase the power output to 350hp. If we apply the same 14.7 psi of boost to the 350hp, we can now reach 700hp. The extra 50hp offered by the cam swap increased to 100hp under boost! The key here is to do everything you can to improve the power output of the naturally aspirated motor prior to adding boost, which includes cam timing.

To get things started, we ran the 5.3L motor naturally aspirated with a set of Hooker 1 7/8-inch headers. Not ideal for the mild 5.3L, but it’s what we had laying around.

For our test, we performed the cam swap on the turbo motor. We also included a naturally aspirated baseline run with the stock cam prior to the installation of the turbo kit. We did so mostly for our own benefit – making sure our DIY-turbo system was performing as it should before performing the cam swap. The test motor was your basic bread-n-butter beater – a junkyard 5.3L snatched from a local LKQ Pic-a-Part.

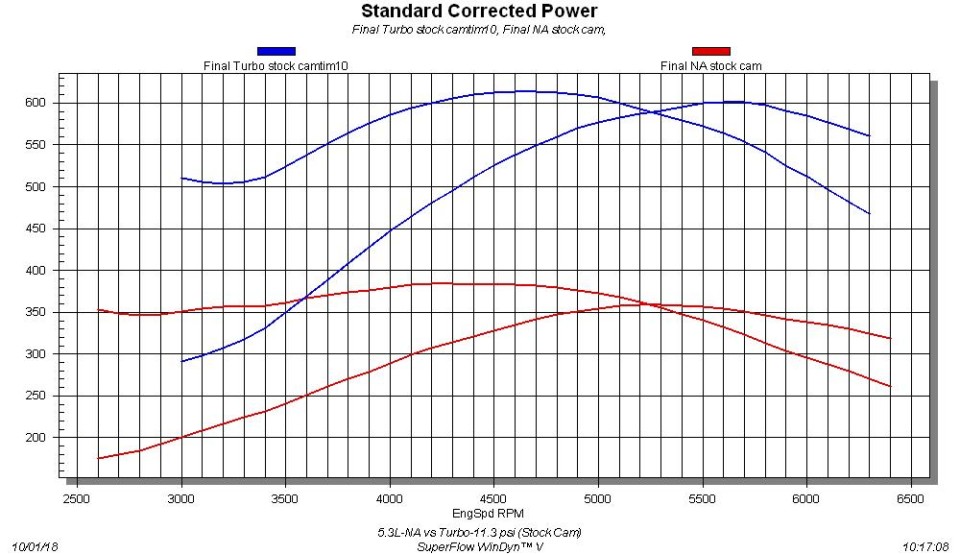

Run on the dyno in naturally-aspirated trim with the TBSS intake manifold and stock LM7 cam, the 5.3L produced 359hp at 5,300 rpm and 384 lb-ft of torque at 4,200 rpm.

The 5.3L LM7 is a favorite among turbo LS enthusiasts. Prior to our test, the 5.3L received increased ring gap, new Fel Pro head gaskets, and ARP head studs. With the cam swap in mind, we also upgraded the stock truck valve springs to a set of 26918 springs from COMP Cams. We replaced the stock (early) truck intake with a Trailblazer SS (TBSS) manifold equipped with FAST 89-pound injectors. The TBSS intake was fed by a FAST 92mm throttle body. Run with a set of 1 7/8-inch, Hooker Headers, the naturally aspirated 5.3L produced 357hp at 5,600 rpm and 383 lb-ft of torque at 4,200 rpm.

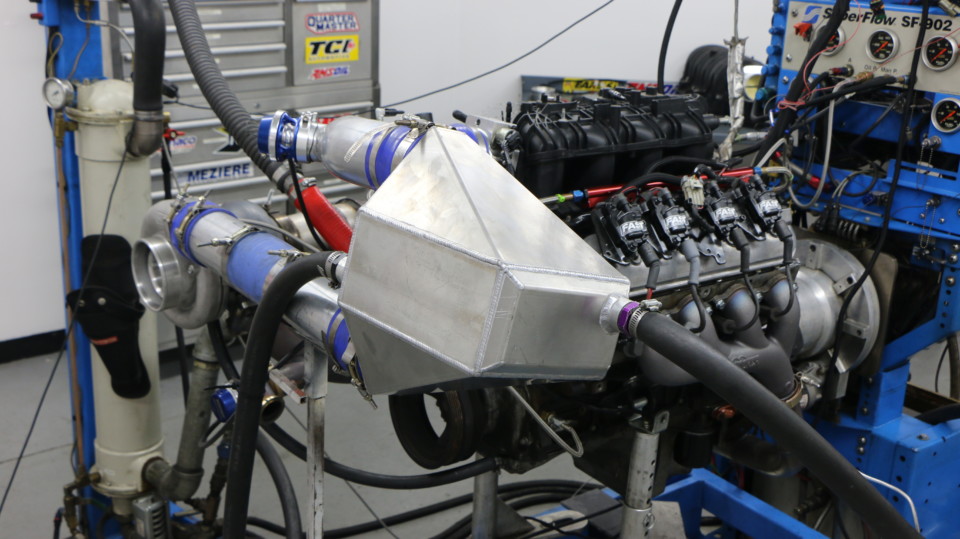

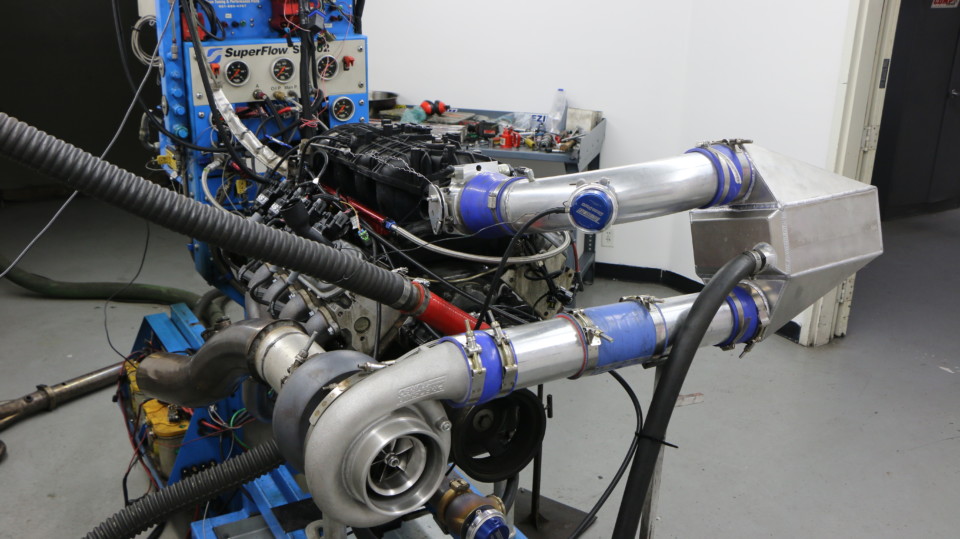

To run our turbo cam test, we configured the 5.3L with a homemade, DIY-turbo system. The basics of our turbo kit included Hooker cast manifolds, a custom 2.5-inch cross-under merge pipe, and 7675 PTE turbo. The Precision turbo was capable of supporting over 1,200hp, or more than enough for our little 5.3L. The PTE 7675 fed boost through a sizable air-to-water intercooler from Procharger. Like the turbo, the intercooler was oversized for our application and was fed a steady diet of 85-degree dyno water.

The manifolds featured a cross-under tube to channel the exhaust from the driver’s side to the passenger’s side merge manifold.

We fabricated a single 90-degree bend that connected the T4 turbo-flange on one end to the 3.0-inch V-band on the exit of the Hooker turbo manifold. This custom adapter also featured a provision for a single 45mm Hypergate wastegate from TurboSmart. In addition to the wastegate, TurboSmart also supplied a Race Port blow-off valve and manual wastegate controller. However, we relied on a 10-psi spring for this test.

Exhaust from the turbo exited through a single 4.0-inch V-band exhaust equipped with an oxygen sensor bung. Run with the stock cam at a peak boost of 11.0 psi, the turbocharged 5.3L produced 603hp at 5,600 rpm and 612 lb-ft of torque at 4,600 rpm. Now it was time for the stage 2.

The exhaust energy was supplied to a single Precision 7675 turbo. The GT42 PTE turbo featured a 76mm billet wheel, 88mm turbine, and 1.28 AR, divided T4 turbine housing.

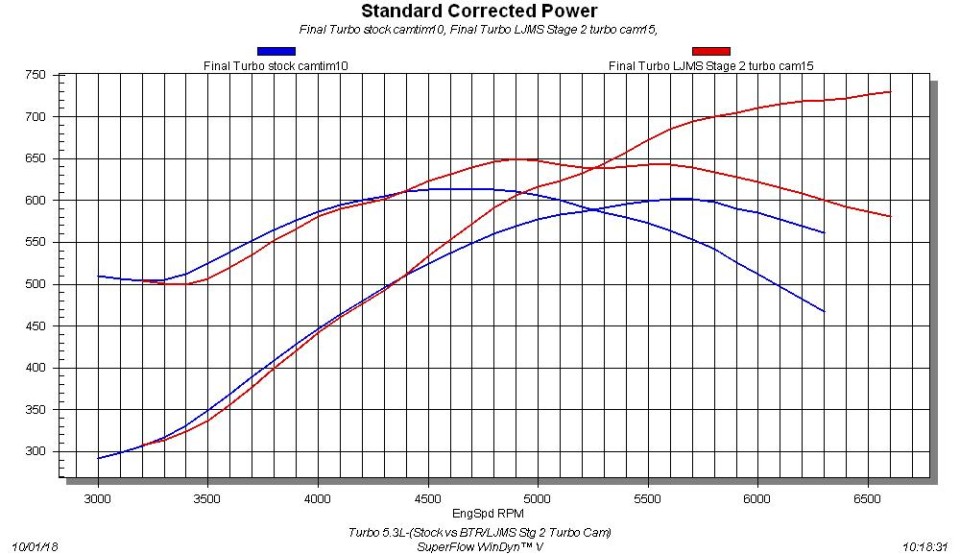

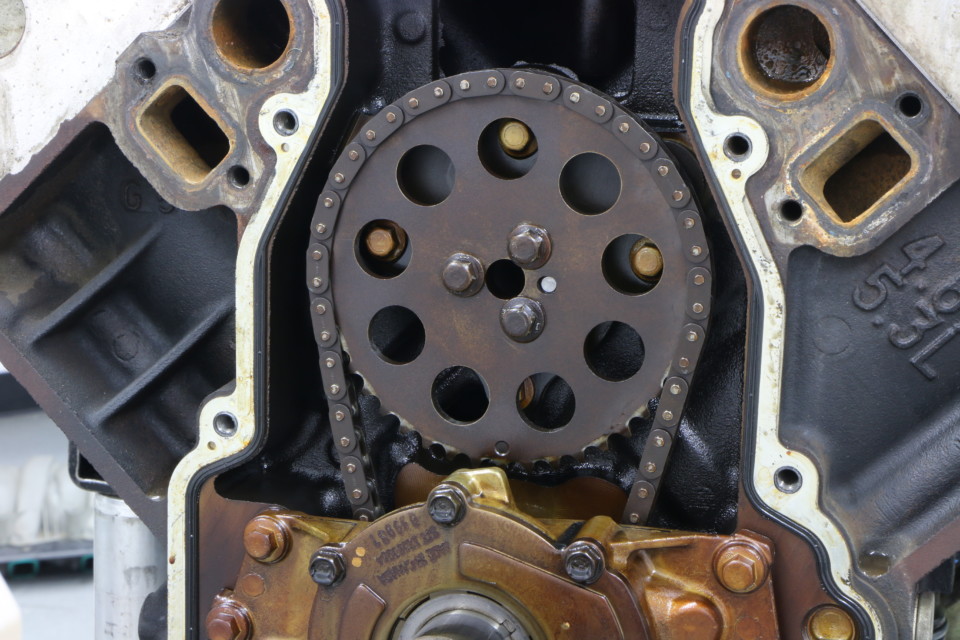

After allowing for a cool down, we tore into the 5.3L to perform the cam swap. Off came the damper, front cover, and cam gear, followed by the cam retaining plate, rockers, and pushrods. Using custom tools (no longer available), we made sure to keep the lifters in place during the cam swap. Out came the stock stick and in went the LJMS Stage 2 turbo cam supplied by Brian Tooley Racing.

The Stage 2 cam offered a sizable increase in specs, jumping to a .605/.598 lift split, a 226/231-degree duration split and 113-degree lsa. The lift increased by roughly .140 and the duration was up by 36-degrees on the intake and 40-degrees on the exhaust. The lsa shifted down by 3-degrees, but the important point is that the opening and closing events were designed specifically for a turbo LS application.

Boost was controlled by a single Hyper-Gate45 wastegate from Turbo Smart. The wastegate was equipped with a 10-psi spring.

After installation of the DIY-turbo system, the turbo 5.3L produced 603hp at 5,600 rpm and 612 lb-ft of torque at 4,600 rpm. Now, it was time for a cam change.

Removal of the front cover provided access to the factory timing gear. After lining up the marks for TDC, we removed the cam gear, followed by the cam retaining plate.

Designed by LJMS and supplied by Brian Tooley Racing, the Stage 2 turbo cam was made specifically for a turbo application. The Stage 2 cam offered a .605/.598 lift split, a 226/231-degree duration split, and 113-degree lsa.

Run with the new turbo cam, the boosted 5.3L produced 730hp (actually 729.8hp) at 6,600 rpm and 649 lb-ft of torque at 4,900 rpm. The peak was almost identical (11.0 vs 11.3 psi), so the cam offered peak-to-peak gains of nearly 130hp. The gains out past 6,000 rpm exceeded 150hp (at the same boost!), which obviously sets the stage for even more power.

Obviously, they did their homework over at LJMS, as the turbo cam improved the power output of the boosted 5.3L to 730hp (729.8) at a higher 6,600 rpm and 649 lb-ft of torque at 4,900 rpm. The wilder cam timing traded off a few lb-ft of torque below 4,300 rpm, but offered peak-to-peak gains of 127hp and 37 lb-ft of torque.

The gains exceeded 150hp higher in the rev range and all the extra power is right where it can be taken full advantage of at the drag strip (or for any run through the gears). Since we ran this test at just 11 psi, the stage is set for even more power from this LJMS-cammed 5.3L with higher boost!

Adding boost to any LS motor improves the power output greatly, even one with a stock bottom end, stock cam, and stock heads. This 5.3L featured all stock (original) internals with extra ring gap (on the original stock rings), stock 706 heads with a spring upgrade, and a stock TBSS intake manifold. Run with the stock LM7 cam, headers, and the Holley HP management system, the naturally aspirated 5.3L produced 357hp at 5,300 rpm and 383 lb-ft of torque at 4,200 rpm.

After adding 11.0 psi of boost from the Holley turbo system, Precision 7675 turbo, and Procharger intercooler, the power output jumped to 603hp at 6,500 rpm and 612 lb-ft of torque at 4,600 rpm. Though this was a solid gain, we couldn’t help but wonder how much the stock cam was holding us back.

It seems obvious from the looks of the graph that the stock LM7 cam was indeed holding us back. After installation of the BTR/LJMS Stage 2 turbo cam, the power output of the turbo 5.3L jumped from a hair above 600hp to 730hp at 6,600 rpm and 649 lb-ft of torque at 4,900 rpm.

The cam improved the power output by nearly 130hp, with gains exceeding 150hp higher in the rev range. Not only did the motor make considerably more power at the same boost level, but it allowed us to rev the motor past 6,500 rpm. The extra RPM would certainly come in handy at the drag strip.