Today’s standard of performance street cred now stands at four digits. Everyone wants more than 1,000 horsepower, and thanks to healthy modern engines and efficient power adders, that goal is definitely attainable. A proponent of the Twin Vortices Series blower technology for many years, VMP Performance had achieved those numbers with its supercharger, but the company wasn’t about to rest on its laurels.

The Gen3R solidly blew our previous record out of the water and we are just starting to realize the true potential of the Eaton 2.65-liter rotor pack. — Justin Starkey, VMP Performance

The result of its continued innovation is the latest Stage 3 2.65-liter VMP Gen3R supercharger, which recently pushed the company’s Track Attack project car beyond 1,141 horsepower at the rear wheels.

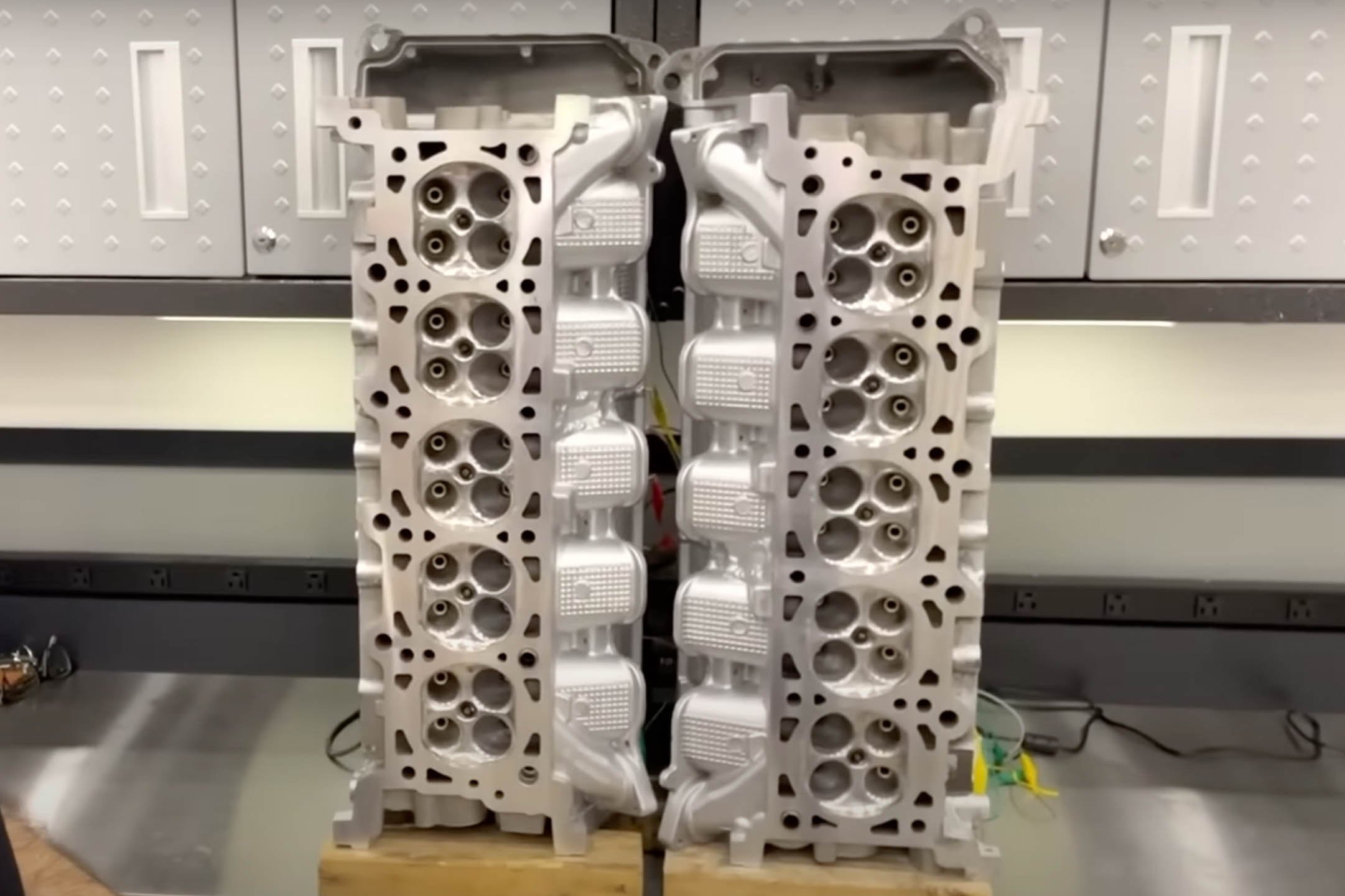

The result of a partnership between VMP Performance and Magnuson Superchargers, the latest Stage 3 Gen3R TVS supercharger has proven quite potent. It pushed VMP’s own Track Attack project car to break its own stock engine rear-wheel horsepower record. Helping it achieve that power level is the new VMP Super Mono163R throttle body for ’15-’17 Coyotes, which features ’15+ Mustang electronics. It features a whopping 16.3 sq-in opening that provides plenty of airflow as delivered by a JLT 125mm CAI and race filter. (Photo Credit: VMP Performance)

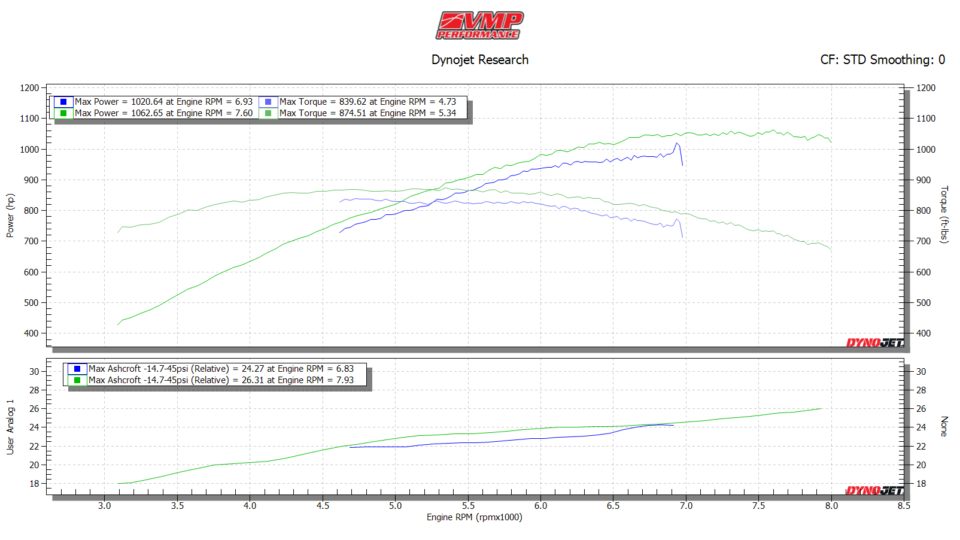

“In early 2018, with the launch of the first VMP Gen3, we decided to push our new blower, and our prized SEMA car, to the limit. Back then, the 2.65L TVS rotors were a huge upgrade from the tried and true 2.3-liter TVS rotorpack. We knew they would perform, but we didn’t know what they would do on a stock Gen2 Coyote 5.0-liter engine,” Justin Starkey, President of VMP Performance, told us. “Dyno testing at low boost showed very promising results, with the fuel tank full of C16 race fuel, and Joe Goodnough’s blessing on the tune, we started to lean on it. Each pulley change yielded more and more power. We eventually hit 1,020 rear-wheel horsepower with a 63mm/2.4-inch upper pulley, a VMP 173mm throttle body, and a 5-percent-overdrive lower pulley. The car had a stock fuel system and was starting to go lean, so we were careful not to rev it over 7,000 rpm, even though the Coyote is capable of over 8,000 rpm. At the time, it was a record for a stock Coyote long-block, with the exception of oil-pump gears and crank sprocket upgrade.“

It would be easy to celebrate those results and leave the blower be. Instead, VMP Performance developed a partnership with Magnuson Superchargers to create a R-model version of the vaunted Gen3 blower that further optimized the airflow feeding the Eaton 2650 rotorpack via the use of rapid prototyping and airflow modeling.

“…The big 150-degree turn from the throttle body into the rotors needed a lot of work. Through prototyping, airflow modeling, and the combined experience of Magnuson and VMP, we made some big changes,” Justin explained. “We pushed internal volume to the package limits, while cleaning up the overall shape, and most importantly the short-turn radius. The inside rotor always gets starved for air, and the Gen3R limits this starvation. Our new blower still fit beautifully under the stock hood with no modifications to the cowl.”

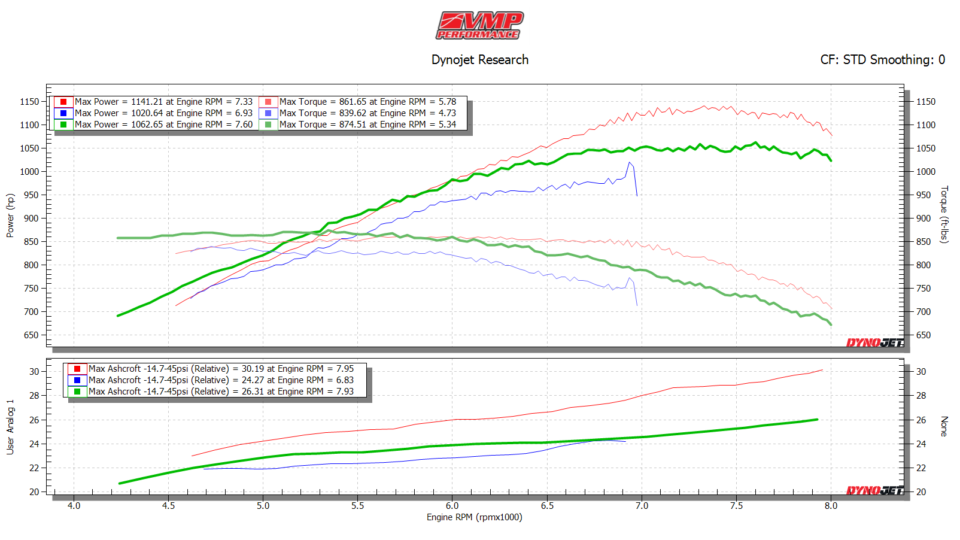

Running a safe but sharp VMP custom calibration created by tuner Joe Goodnough, Track Attack picked up an additional 81 horsepower while running 5 degrees less timing thanks to the efficiency from the latest stage of VMP Gen3R supercharger.

With a first example in hand, the company tested the new Gen3R on an customer’s car with great success, but Justin didn’t want to push another person’s pride and joy to the breaking point.

“Track Attack still had a stock long-block sans the requisite oil-pump gear/crankshaft sprocket upgrade. It however, was limited by the stock fuel system,” Justin said. “Joe and I knew that if we pushed Track Attack again it would need plenty of fuel, and E85, to give it a fighting chance. Luckily, VMP was developing a Coyote fuel system upgrade kit, and Track Attack was chosen as the test mule for installation video and dyno testing.”

In addition to the dual-pump fuel system and big injectors, Track Attack would serve as the test bed for another stage of Gen3R TVS performance.

“I prepped a VMP Gen3R with ‘secret sauce’ internal modifications, the next ‘stage’ of the Magnuson patent-pending port technology,” Justin said. “Track attack’s fuel system was installed, the tank was full of E85, it was D-day on the dyno. Would we break the record, or would we break the engine?”

With the latest technology in the blower, the VMP team eased into the testing with a 2.6-inch upper pulley and super safe timing. Running the previous-generation Gen3 combo needed 26 degrees of advance to produce four digits, but this one only needed 21 degrees. They eventually moved up to a VMP Griptec 2.4-inch, 10-rib pulley and packed the intercooler reservoir with ice. The results easily surpassed Track Attack‘s previous stock-engine record.

Initial testing of the Gen3R TVS supercharger yielded solid gains of 42.01 horsepower and 34.89 lb-ft of torque on a customer’s 2015 Mustang GT Saleen powered by a Coyote with forged internals.

“After the graph came up we were elated, it made 1,141 rear-wheel horsepower with the standard correction factor. There is some controversy about which correction factor to use, so we also supplied graphs in SAE format, and also with smoothing at five. No matter how you look at it, a stock Coyote engine made over 1,100 rear-wheel horsepower on pump E85 fuel,” Justin said. “The heads have never been off this engine, the stock cams are still in it, and nothing at all is ported. We used all VMP parts and VMP custom tuning, which anyone can purchase if they were going to re-create this combination. With a built bottom-end, ported intake manifold, ported cylinder heads and aftermarket cams it would probably make another 150-200 rear-wheel horsepower.”

This level of performance is certainly impressive, but VMP plans to continue pushing this technology to see just how far it can go.

Here’s a look at the evolution of VMP Gen3 TVS performance. The original Gen3 blower delivers an impressive 1,020.64 hp/839.65 lb-ft at the wheels, while the Stage 2 Gen3R upped the ante to 1,062.65/874.51. Stepping up to the latest Stage 3 Gen3R variant delivered a whopping 1,141.21 and 861.65 with a really soft timing curve, especially down low. Even with the more conservative SAE correction factor, the latest Track Attack combo still pumped out 1,115.42 horsepower and 844.24 lb-ft of torque at the rear wheels.

“We knew the blower would do at least 1,100 rear-wheel horsepower on Track Attack, but we weren’t sure how much farther it would go,” Justin added. “The Gen3R solidly blew our previous record out of the water and we are just starting to realize the true potential of the Eaton 2.65-liter rotor pack. This is just the beginning of much more to come from VMP.”

For more on the latest VMP Performance Gen3R TVS superchargers, you can visit the company‘s site here.

VMP Track Attack Mods

• 15-percent overdrive lower pulley

• 63mm/2.4-inch upper blower pulley

• Billet oil-pump gears

• Cervini’s side exhaust

• Dynatech long-tube headers

• E85 fuel

• Forged crank sprocket

• G-Force Engineering halfshafts

• Injectors Dynamics ID1300x Injectors

• JLT Performance 125mm cold-air intake

• Mantic twin-disc clutch

• VMP Coyote fuel system

• VMP custom calibration

• VMP Gen3R 2.65-liter TVS supercharger

• VMP Super Mono 163R throttle body