There’s no doubt among performance aftermarket experts that heat is a bad thing. It causes components, both electrical and mechanical, to be short-lived if not given the proper protection. And while the OEMs do an excellent job of keeping the heat at bay under the hood of a vehicle, what happens if you add an additional heat source in a turbocharger? Thankfully we have companies like Design Engineering Inc. (DEI) that built its business around “Thermal Tuning Products.”

The Truck

Fast trucks are a pretty common occurrence here in the Lone Star State of Texas. And while the weather is pretty mild most of the year, it’s not uncommon to see 100-plus degree days in the summer months. Trying to keep a stock vehicle cool in this environment isn’t much of a problem, but keeping the underhood temperatures at bay can be an issue when you add a turbo system.

You can see in this image that the heat is taking its toll on the factory loom, leaving the wires exposed to the elements.

Our 2000 Chevy Silverado is a typical build, with nothing real exotic. It houses a 6.0-liter engine, Texas Speed and Performance cam and valvetrain, Deatschwerks fuel system, Moser Fab 9-inch rear end, and a Trick Turbo system. The truck makes a decent amount of power on pump gas, and we love to drive it everywhere we can. The only problem is the Texas summertime heat. The turbo system has been on the truck for about a year now, and we have noticed some changes under the hood.

While some of the anodized parts are changing colors due to excessive heat, the big concern is the wiring loom. Because of the heightened temperatures, the loom is now brittle and crumbles when touched or moved. With the loom disintegrating, more and more wires are being exposed to the elements. So when it came time to suppress our Turbo LS-powered 2000 Silverado’s underhood temperatures, we knew who to contact. Steve Garrett, the Creative Director at DEI, was able to help us navigate through their products.

The Heat Is On

Engines generate a lot of heat. And when you add a turbo, things get even more interesting. Since this power adder is driven off the exhaust, you can understand that everything under the hood will be affected by heat-soak.

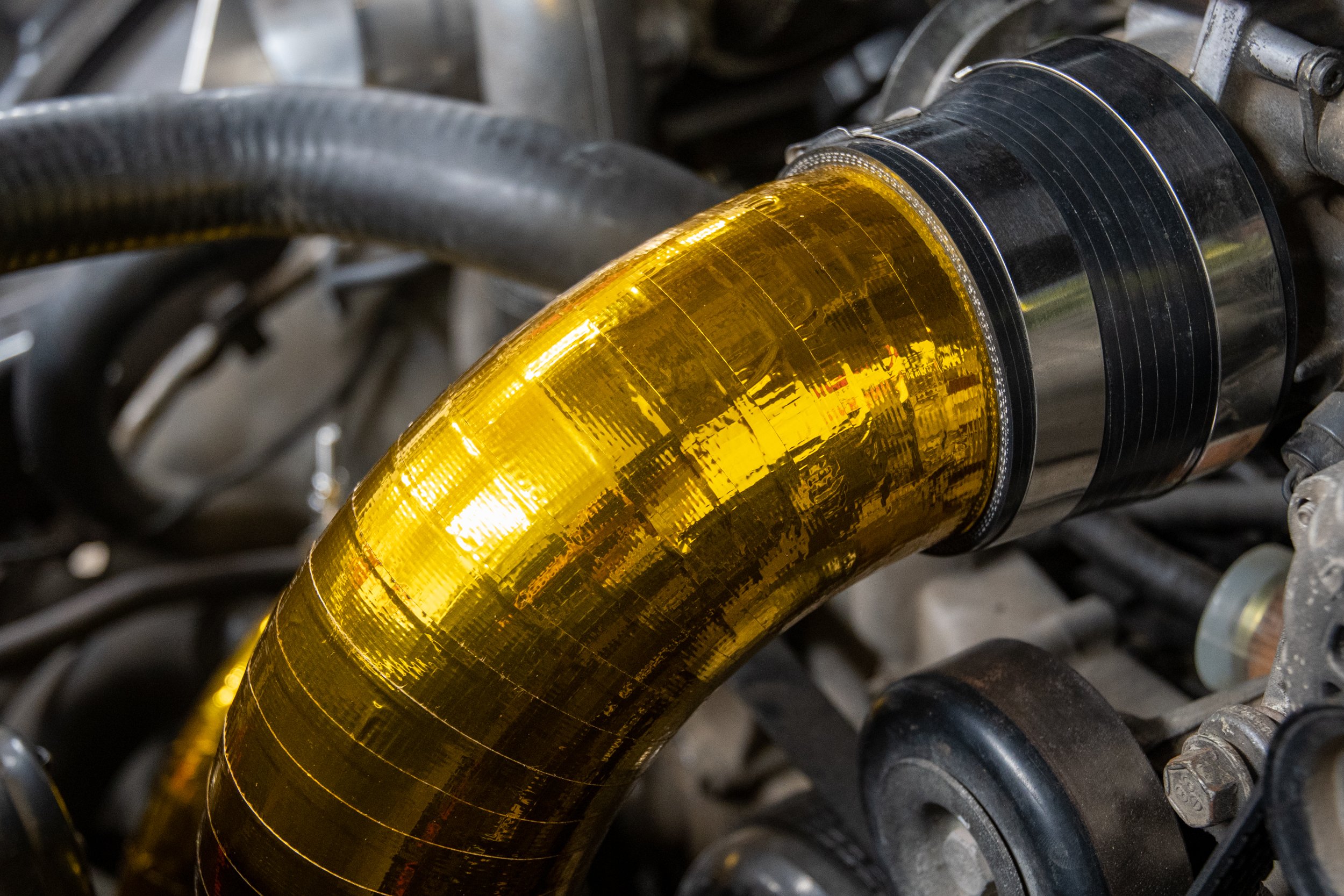

The aluminum piping on the cold side needs protection too. DEI offers a wide variety of products to help fight the heat.

“With a turbo application, it’s a must to wrap exhaust pipes/headers and the downpipe. The heat from a turbo engine is much greater than naturally-aspirated (N/A). You have a better chance of the heat damaging components like lines and hoses,” Garrett explains. “A wrap allows for a significant reduction of heat on both N/A and boosted engines. With any application, you can achieve reduced air intake temperature because you get a reduction of up to 50-percent of the heat coming off the turbo or headers. This keeps the underhood temperatures at bay, in turn making intake temps cooler.”

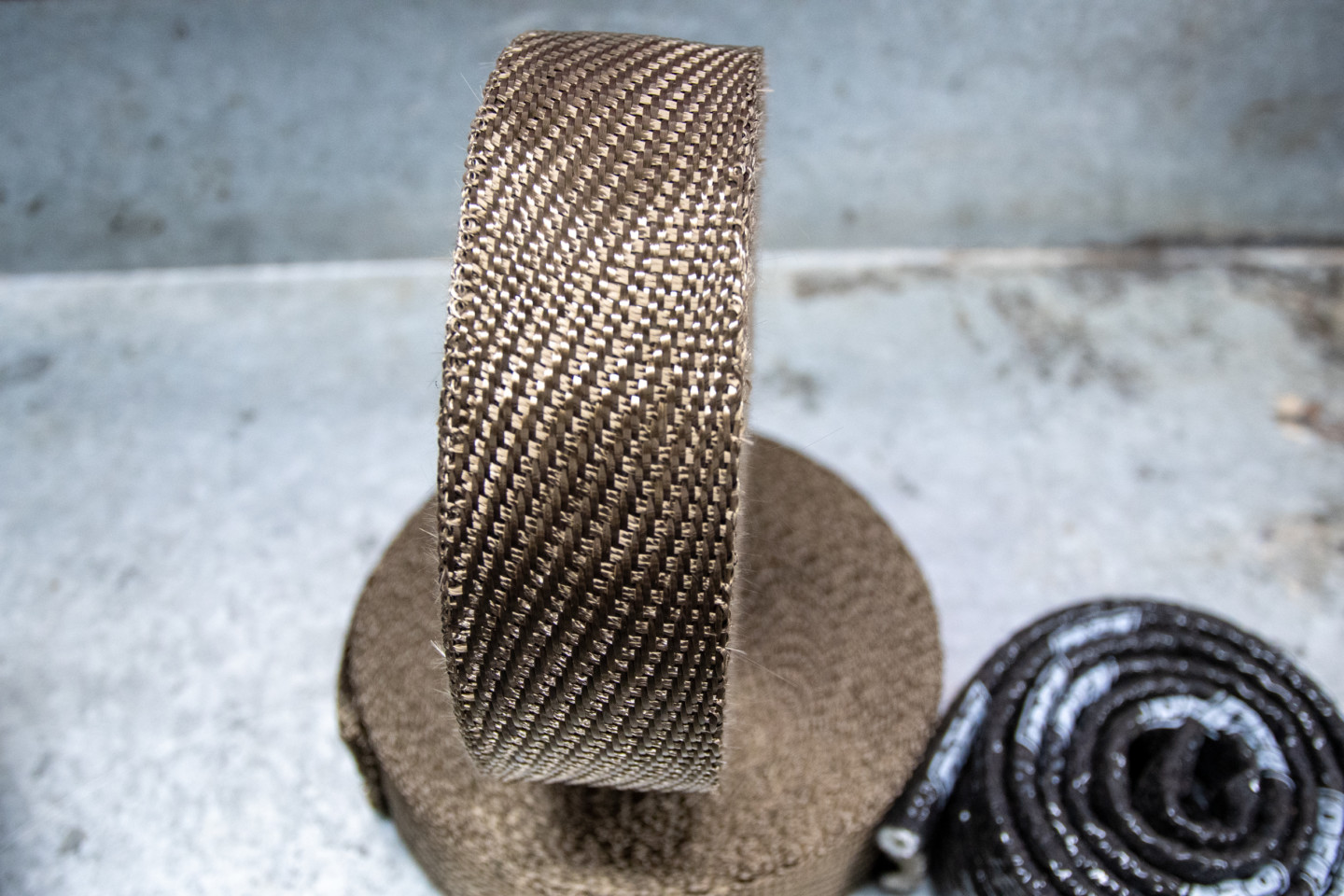

One thing to note before you get started, in the picture, you can see that the left side of the wrap is stitched. You will wrap the material so that this part is exposed, meaning, the side without the stitch will be cover with the overlap of the next layer.

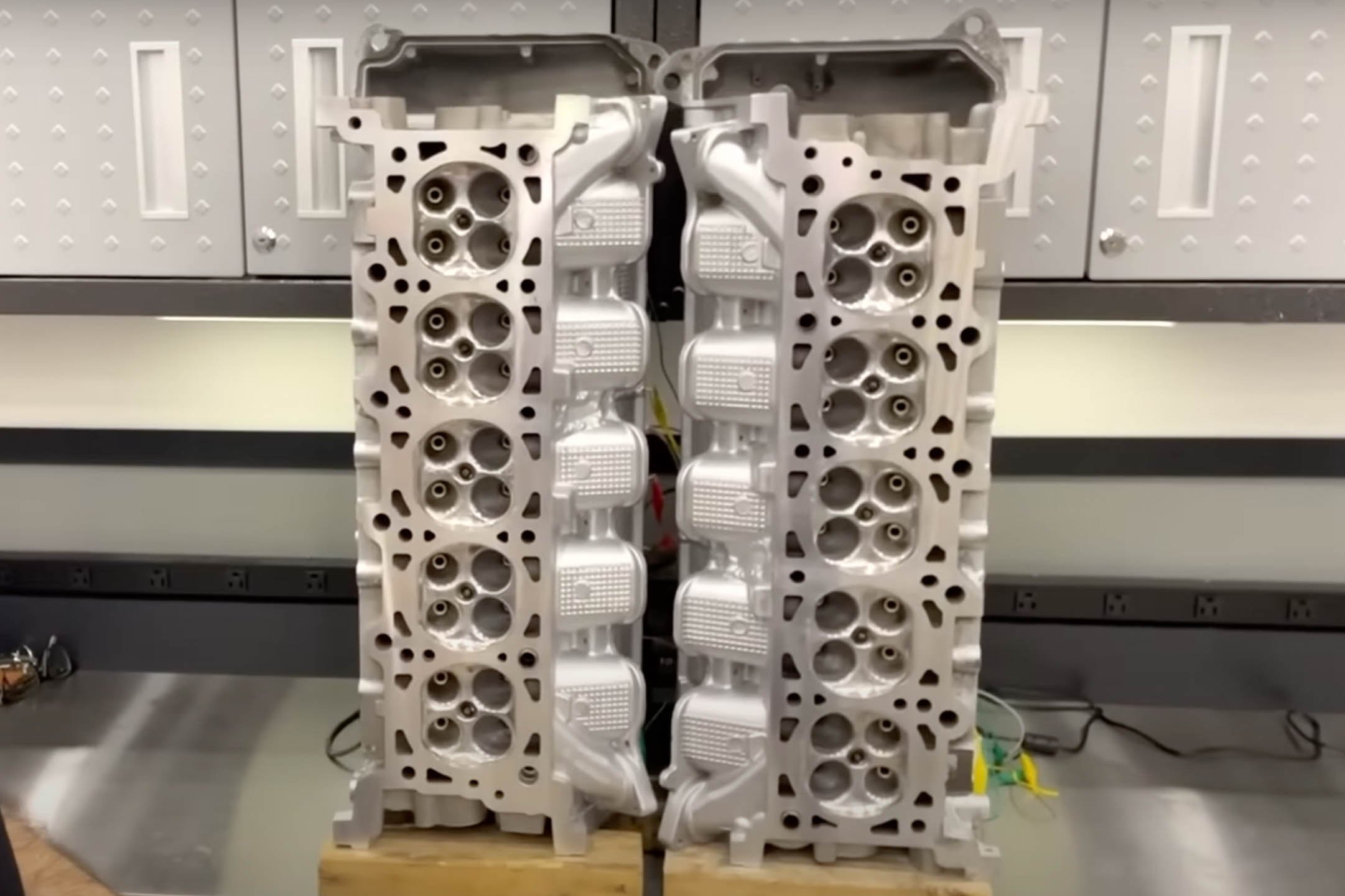

Our first step to combat the added heat from the turbo was to wrap the exhaust manifolds and crossover pipe. For this, we chose DEI’s Titanium exhaust wrap. This material is made from pulverized lava rock, stranded into a fiber material, and woven into a strip. DEI’s Titanium wrap is engineered to be stronger than most wraps and more durable for improved thermal performance and reliability and is perfect for any automotive application.

After we removed both manifolds, we cleaned them up and began the wrapping process.

Wrap It Up

Depending on your header or exhaust manifold design, the wrapping process can be pretty tedious. One thing that made the process easier for us was to tape the wrap’s ends to keep the frayed edges at bay. We just used the standard blue masking tape. Another tip is to do a couple of practice wraps before committing to the final product. We wrapped the manifold several different times to figure out the best gameplan.

With some of the older wrap products, DEI recommends wetting the material. However, you do not need to dampen the Titanium wrap material. This product is more pliable than the others and is much easier to install.

Since there was no way to get total coverage on the turbo manifold, we needed to do a couple of layers. We started with the runner closest to the turbo and wrapped the runner from the top, bringing it down on the manifold’s log. We then secured that piece with a zip tie and then worked on the rest of the runners until we made it to the last one.

When we started the last runner, we worked our way down the log back to where the turbo bolts up. As we got to the zip ties that were holding the wrap, we cut them and then proceeded to wrap, securing the material underneath. When we arrived at the turbo mount, we used the supplied metal ties and the DEI tool to secure everything. This handy tool makes it extremely easy to tighten up the DEI ties.

With the turbo manifold complete, we turned our attention to the drivers side manifold and the exhaust crossover. While the exhaust manifold was a little challenging to wrap, the crossover was super simple. We applied the wrap with about a ¼-inch overlay and worked our way around using the metal ties as needed.

We Love Gold

While the wrap keeps the heat in the manifolds and exhaust pipes, we needed a product to keep the heat out of the turbo system’s cold side. To achieve this, we used DEI’s Reflect-A-Gold heat reflective tape.

“The advantage of the Reflect-A-Gold line is the reflectivity. It will reflect a higher amount of heat and radiant heat than the aluminized or mylar faced products,” Garrett explained. “These properties make it the perfect choice for piping that routes around headers, exhausts, and engines. It’s a very thin material so that it can be applied to areas with little clearance. For vehicles that are weight conscious, like racing applications, there are no concerns about it adding any mass to the car.”

While Reflect-A-Gold is designed for use on piping, firewalls, bulkheads, and floors, it can be used on just about anything else you can think of that needs heat protection. This product is easy to apply and can handle continuous temperatures up to 800-degrees Fahrenheit. And, since it’s a tape, it’s easy to apply with a peel-and-stick application.

We cut the Reflect-A-Gold into small strips and applied them one at a time. This keeps the material wrinkle-free and gives it a clean look for you guys with OCD.

Before getting started, we needed to remove all of the cold-side piping from the truck. After it was separated, we then cleaned it per Garrett’s instructions. He said, “Wiping down components with isopropyl alcohol helps with adhesion, and scuffing the surface helps give the adhesive a little more bite.”

Before you get started, it’s beneficial to know there are a couple of ways to wrap the Reflect-A-Gold product. If you use the wrap in one piece, depending on the tube’s radius, the finished product will have wrinkles. You can also cut the tape in strips and apply it a layer at a time. While this process takes a lot longer, it makes for a clean, wrinkle-free finish. We decided to apply the Reflect-A-Gold both ways to show you the results.

You will get a nice uniform look with the strip method. Even though this process takes a while, it’s worth it in our opinion.

Since the pipe going to the throttle body is very obvious with the hood up, we used the strip method to make it look tidy. For this method, we measure the tubing’s circumference and then cut strips of tape. With a piece in hand, we then cut the sections in half width-wise. We then applied each piece one at a time, overlapping it by an 1/8-inch. On the rest of the piping, which is not that visible, we wrapped it in one piece. This doesn’t look quite as nice, but it works just the same and is a much quicker process.

If you don’t use the strip method, the product will have wrinkles around the radius areas. While the doesn’t look as clean as the other pipe, it works just the same for heat reflection and is faster to apply.

In this image, it’s easy to tell which radius we got lazy with and didn’t cut the Reflect-A-Gold into smaller pieces.

Hose Protection

As you know, most turbos require a high-pressure oil line coming from the engine to lubricate the bearings. The turbo will also have a return line going back to the oil pan. To keep these lines from breaking down from the heat, we installed the Fire Sleeve. This product not only insulates our hoses, but it’s also fireproof.

Garrett said, “Our Fire Wrap 3000 has super -thick insulation on the inside. This gives it great insulating property for whatever line you apply it. Also, the thick silicone coating is excellent to prevent abrasions and rub through on lines and hose, and you don’t need to remove the hose to install it. With the hook and loop edge, you can wrap it around and close it up. The NHRA also accepts it for fuel, oil, and brake line protection.”

We used Fire Wrap 3000 for both our high-pressure oil line and return line on our turbo system. This product will protect the hoses from direct heat up to 500-degrees Fahrenheit.

DEI constructs the Fire Sleeve from high-temperature resistant braided glass, which is woven into a sleeve and then coated with 100-percent iron oxide silicone rubber. The thermal insulator sleeve protects from direct heat up to 500-degrees Fahrenheit.

The Turbo Shield

The last order of business is to take care of excessive heat that is emitted by the exhaust housing on the turbocharger. DEI makes several different applications and materials to combat this problem.

For our application, we chose the GEN-3 Titanium Turbo Shield. This product is DEI’s most advanced cover to date and offers some unique features like silica insulation that keeps the heat in the turbo shield and turbo housing. This insulation also had a low thermal conductivity, making it one of the best insulators on the market.

You will also find stainless steel, glass fiber, and silicone on the inside of the Titanium Turbo Shield. While this combination adds to the product’s thermal properties, it also increases seam strength, durability, and insulation value. This item will hold up against high temperatures (1800°F of direct heat, and 2500°F of radiant heat) and will not break down or become brittle. We can’t say the same about our current cover that is already showing signs of wear.

If you need a turbo cover, but you’re not sure what size to order, DEI has a handy turbo measurement chart on its website. All you need to do is measure the circumference and width of the turbo exhaust housing, and then you will know which size to order.

You can tell that our -AN line has taken a beating from the heat. When we first installed it, the fitting was black and not bronze. We expect the DEI Titanium Turbo Sheild will help with this problem in the future.

The GEN-3 Titanium Turbo Shield offers an excellent snug fit on our 76mm turbo, and the installation was easy. After we had the product on the turbo, we used the supplied safety wire to secure it into place.

While The Silverado’s engine looks a lot different under the hood with the DEI products, we also expect to see some significant changes with the engine’s heat and a cooler air charge. We plan on reporting back with results as soon as we get the old Chevy roadworthy again, so stay tuned.