Every old-school hot rodder knows moving air through an engine is a requirement for making power. Before the cars we now collect came with computers, the long-tube header was a staple in the performance realm. It is no secret that factory-installed exhaust manifolds hinder power production. But, as advanced as cars have become, are long-tube headers still a requirement? If so, what are the ramifications you’ll encounter after installing a long-tube header? For starters, your car might not be legal for street use.

We decided to reach out to the professionals at Pertronix (makers of JBA Headers, Doug’s Headers, and Patriot Headers) and Holley Performance Parts (parent company of Hooker Headers) to find out just what gains can be had by installing a “shorty” header on a modern muscle car, and how CARB/EPA legality plays into header selection.

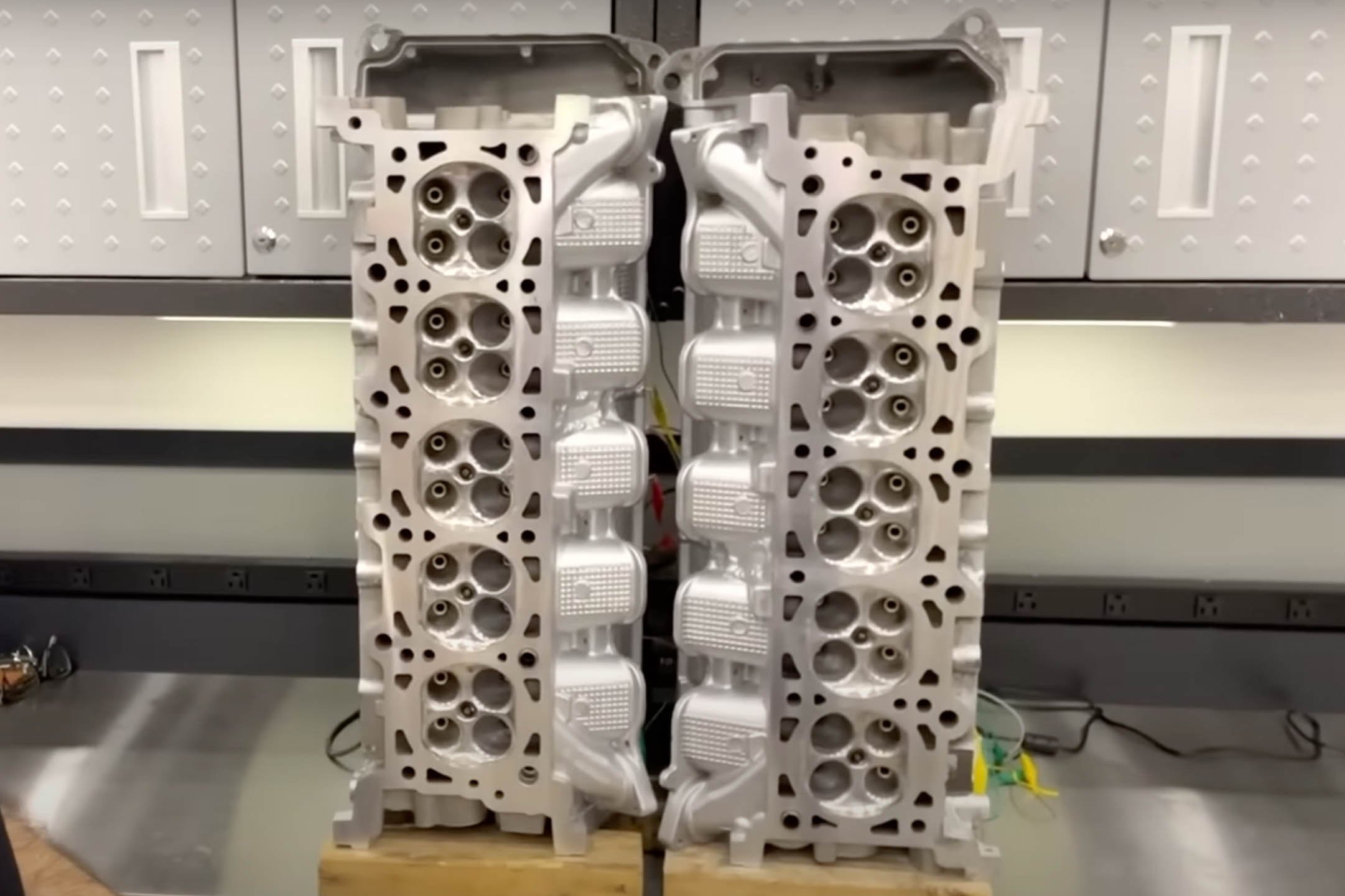

Above shows the difference between the shorty header and a long tube header. The long-tube header eliminates the catalytic converter (on some applications), making it illegal for street use on many cat-equipped vehicles. The shorty retains the OEM cat(s), therefore, it can be made legal in all 50 states.

We realize headers will help make more power and torque on nearly any engine when upgrading the stock, cast manifold. That thought should hold up because making power is all about airflow, right? As we found out, yes and no. Actually, it’s more about optimizing how the exhaust gasses are removed from the engine’s combustion chamber. More on that in a minute.

A short-tube header is going to be an easier install, typically bolts up to the factory exhaust, and many times can better improve the areas of the RPM band where a street car spends most of its time. – Evan Perkins, Holley

Headers Are Better, Because?

If an internal combustion engine is just an air pump that contains controlled explosions, that would mean how the air exits the engine is just as important as how it gets in. As a piston makes it through the exhaust stroke, the burned gases are pushed past the opening exhaust valve, into the exhaust manifold or header, and ultimately, out the tailpipe. By nature, OE manifolds have noticeably short runners that converge into a common plenum. This causes the exhaust gases from each cylinder to collide and build up pressure in the manifold.

This backpressure not only prevents all of the exhaust gases from being removed from the chamber, but the proximity of the plenum to all of the engine’s exhaust ports can allow gasses from one cylinder to travel back in another cylinder during cam overlap. If all exhaust gas is not removed from the cylinder before the intake charge is introduced, that fresh charge will be diluted, and less power delivered.

Why Do The OEMs Use Manifolds?

The use of exhaust manifolds can be boiled down to multiple reasons, but a few main ones are: cast manifolds are cheaper to produce, those thick cast-iron structures are great for retaining heat for emissions reasons, are very durable, and help keep unwanted exhaust noise down. The OEMs are always battling to keep temperatures and engine noise down in the engine bay.

The manifold (top) creates a bottleneck in airflow because the first three tubes actually converge in the first tube. The shorty header (bottom) flows much better, as all primary tubes have an uninterrupted flow to the collector.

Also, assembly of long-tube headers is a labor-intensive process. The tubes require careful routing above, through, and below many other parts of the car. Ideally, the length of the tubes will be fine-tuned for the engine and each one will be as close to equal as possible, which makes fitment even more challenging. Finally, parts spec’d out for production cars have to consider the entire picture: delivery logistics, manufacture time constraints, assembly packaging, and use in many car models.

The aftermarket performance arena saw a need for an exhaust “manifold” that could outflow a stock manifold, remain emissions compliant, and boost power — enter the “shorty” header. As car emissions advance, catalytic converters slowly inch closer to the engine. In fact, most are now attached directly to the exhaust manifold.

Shorty headers are designed to accept the stock exhaust, including the catalytic converters. This makes them more acceptable to emissions standards.

The Short And Long Of It

Shorty headers are better than most stock manifolds because, although they also offer short runners like a manifold, they do not converge (in series) into a single plenum/log like a manifold. The shorty header utilizes the same termination style as a long-tube header — the collector. So, why not just use a long-tube header?

“Long tubes are not an option for CARB approval,” states Don Lindfors, director of exhaust R&D for Pertronix. “One of the requirements for CARB approval is you cannot move the catalytic converter, and there has been a trend over the years to move the cat closer and closer to the exhaust port to help light the cat off on cold start.”

According to Evan Perkins, digital content manager at Holley, “A long-tube header, when properly tuned to the application, will show strong improvements in the middle of the RPM band all the way to the top. There are many more variables to consider such as primary-tube length, diameter, and routing, so to say a long-tube header universally works best above ‘this RPM’ wouldn’t be accurate. There is so much testing and engineering that goes into an application-specific set of headers.

“In general, a short-tube header is going to be an easier install, typically bolts up to the factory exhaust, and many times can better improve the areas of the RPM band where a street car spends most of its time.”

Since the primary-tube diameter plays a crucial role in performance, Evan has this to include, “The primary-tube diameter needed is going to depend 100-percent on the engine application. Is it a 4.8-liter LS or a 6.0-liter engine? Tube diameter is a function of engine displacement and desired operating RPM. Equal length headers are always optimal. Unequal length headers can cause each cylinder to run differently and have a negative impact on exhaust scavenging.”

Engine design, cam specs, cylinder heads, intake, and the cats themselves are all going to affect the RPM range before the shorty header hurts performance. – Don Lindfors, Pertronix

When it comes to the primary-tube length, Don iterates, “On Cat4ward headers, the primary-tube length is dictated, and restricted, by available space and cat positioning. The ‘equal length’ theory is somewhat polluted, as there are many factors to take into account. Ideally, headers would be as straight as possible with minimal or even no bends. Air flow is laminar — it likes to go straight, it doesn’t really like to turn. Because of this, bends create restrictions that can slow velocity. A lot of this is caused by the boundary layer, which occurs between the air flow and the tubing. In a straight piece of tubing, it is consistent. But when you introduce a bend, the boundary layer tightens up as the air fights to get around the bend causing some restriction. So how does that answer the question?

“In most cases to try and get equal tubing lengths, we have to create more bends. This causes the tube to have more restrictions and act like it is longer than it is. Fortunately, a few inches of length difference doesn’t really change the end result much. The power curve will shift slightly up and down with length changes. I have found, and proven on the dyno many years ago, that this can actually broaden the overall power curve and some cylinders make more power at lower RPM than others. On a long-tube header, this might affect peak power slightly, but in a shorty, you won’t see an appreciable difference. Ideally, we don’t want a drastic difference, but some vehicles leave no choice.”

Collective Results

Two collector dimensions affect the efficiency of any header: length and diameter. The collector length is measured from where the primary tubes end, to the flange where it meets the rest of the exhaust system. The diameter is the inside diameter of the collector tube.

How a collector affects power is by the “scavenging” effect created by the headers. Scavenging the removal of exhaust gasses from the cylinder is an effect created by maintaining the speed (velocity) of exhaust flow. As an example, when the high-speed pulse of exhaust from the primary tube reaches a larger collector, the velocity decreases.

“The idea is to time this negative-pressure wave to coincide with the cam overlap,” states Don, “The low pressure helps draw the incoming intake charge into the cylinder for more complete filling of the cylinder while at the same time, pushing out any residual spent exhaust gases. The timing of these events is mostly controlled by the length of the primary pipes in the header design.”

We’ve all heard the statement that shorty headers are okay for anything under a certain engine RPM and long-tube headers should be considered when spinning above a certain RPM. According to Evan, “There’s no RPM limit for any header, only a bottleneck in airflow, or unoptimized scavenging. These may provide diminishing returns above a certain RPM point. What that point is will be entirely based on the engine application.”

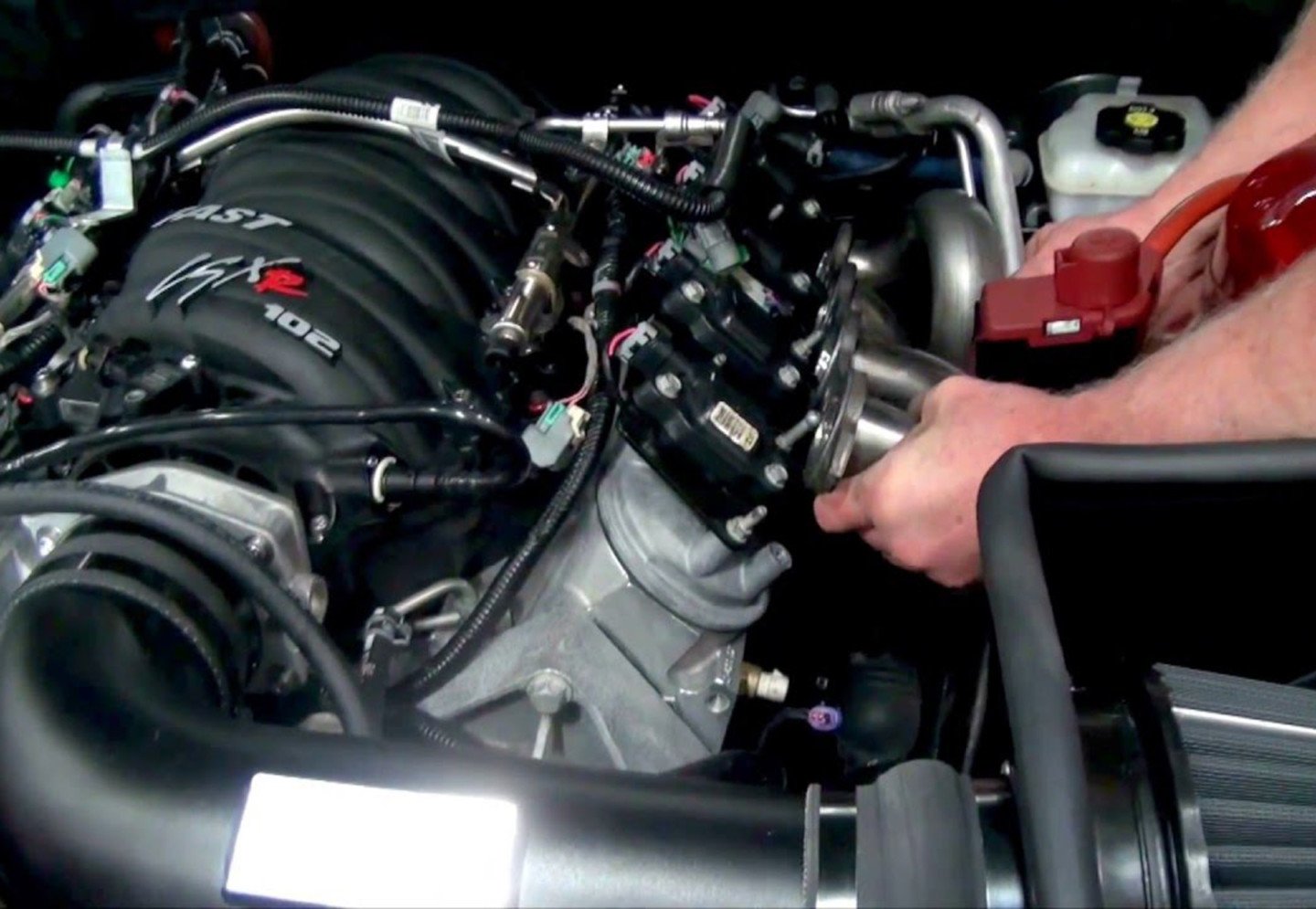

A shorty header is not an overly hard upgrade to complete. If you figure on spending a leisurely day in the garage or driveway, you can complete the task yourself.

According to Don, “the shorty header isn’t going to be a limiting factor in RPM – especially on a late-model, catalytic converter equipped street vehicle. Engine design, cam specs, cylinder heads, intake, and the cats themselves are all going to affect the RPM range before the shorty header hurts performance.”

Since the engine specifics mentioned are the RPM-limiting factors, if an engine is not spending life above 6,000 rpm, why would a “shorty” header benefit the average street enthusiast? “Regarding JBA Cat4Ward headers, they are designed to maximize flow in the given parameters of catalytic converter location,” says Don. “Most factory manifolds (even the tubular “header style” that some OEs make) are not optimized for power – manufacturing processes and ease of assembly-line installation are the main criteria. We are able to free up exhaust flow and improve scavenging over standard manifolds.

Keeping It Legal

One thing to keep in mind is not all shorty headers are created equal. To be used on the street in all 50 states, as Don previously eluded, the shorty header must pass CARB-emissions testing. We asked what is required to pass this certification.

“Short answer is, there must be no increase in emissions under very rigorous testing,” Don affirms. “The cats and all other exhaust-related emissions equipment must be maintained, operational, and in the original location. It’s not the standard SMOG test. It is the same as the OEMs have to do initially to certify the vehicle. This testing is quite involved using specialized fuel and many hours of dyno time.”

When considering a header upgrade for your late-model muscle, Don has this to say, “when looking for late-model 50-state-legal headers, the customer is somewhat limited. As a manufacturer, there is a limited amount that we can do with design due to the space limitations and catalytic converter position. The enthusiast wants to look for a reputable company that has been building legal headers for some time to know they have worked out the quality and durability concerns.

“Also, coated headers are worth the extra money as they keep the heat inside the header which helps increase velocity. It also helps light the cat off quicker to reduce emissions.”

Following that, Evan has this to add, “header choice can make or break an engine in terms of real-world power delivery. We would encourage anyone unsure of the right header to consult one of our technical representatives to make the right call.”

Whether you’re building a nasty street/strip car or just wanting to add a few performance parts to your hot rod because you’re not sure when you might need them, a CARB-certified shorty header could be just what your engine needs to release a few of those pent-up ponies.