Hot rodding today may require a little more effort to stay legal than it did before the late-‘60s when emissions compliance wasn’t a concern. But, with 450-plus horsepower and fuel economy as high as the upper-20s in a modern muscle car, many would argue that “the good old days” are right now. So, it’s a small price to pay.

One company involved in helping you increase horsepower and remain emissions legal is JBA Performance Exhaust. The company’s Cat4Ward shorty headers allow hot rodders to punch up the power of their modern muscle while satisfying any emissions inspector. That’s because of the assigned California Air Resources Board Executive Order (EO) number.

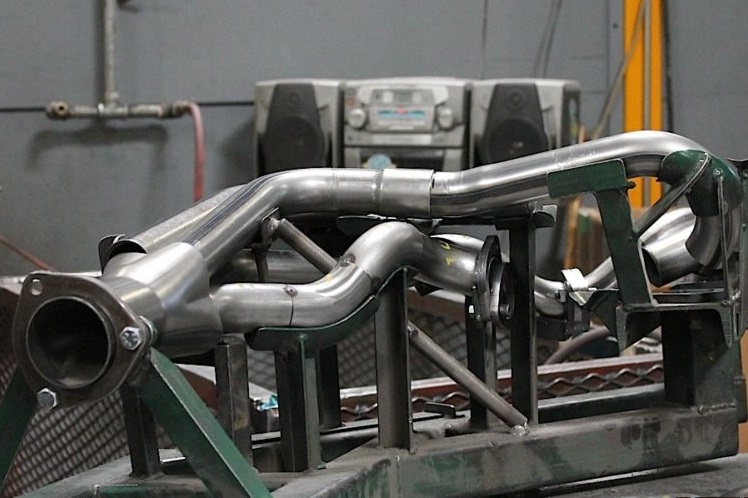

JBA’s Cat4Ward headers are 50-state emissions-legal, and the collectors feature a Fire Cone, which is a smooth transition to increase exhaust flow velocity. They are available in raw stainless-steel or a bright silver or titanium (shown) ceramic coating.

“JBA’s Cat4Ward shorty headers are designed to offer the best possible real-world power increases while staying within the guidelines prescribed by CARB,” says Don Lindfors, director of exhaust R&D for PerTronix, the parent company of the JBA Performance Exhaust brand. “The goal is to increase flow within the design restrictions the regulations require.”

Late-model vehicles have catalytic converters much closer to the exhaust manifold or header, and this original equipment position must be maintained for proper converter operation. That means long-tube headers cannot typically be used.

“This creates issues in design — both because of available room to build a four-tube header and the tube lengths available within the restricted area,” he says. “With older cars — where the cat was under the floorboard — it is possible to design relatively long-tube headers that will still accommodate the cat positioning and function.”

Moving the catalytic converter closer to the engine provides for quicker cold-start warm-up. As catalytic converters have become more free-flowing, having a quick light-off has become more critical. Moving them closer to the engine allows this, Lindfors mentions. “Also, take into consideration changes in O2 reading feedback, since many current cats have the O2 sensor right in the cat itself.”

It used to be said that legal shorty headers were too restrictive to make power, but our years of design and testing have taught us the cats were the biggest hindrance, and those have improved over the years. – Don Lindfors

Anti-reversion is not much of a concern with short headers, Lindfors says, as the catalytic converter helps break up the reversion wave.

“We do add the JBA Fire Cone to the collector, which helps not only with the flow by smoothing the transition, but also to increase exhaust flow velocity.”

Here’s a closer look at the Firecone, which helps ease the transition in the collector and increases exhaust-flow velocity.

It’s becoming a trend for non-performance-oriented engines to have an integral manifold/catalytic converter, Lindfors says, which leaves no room to build a header for those applications.

“The Chevy Colorado V6 and current Jeep V6 are both examples of this. This is somewhat worrisome for the performance aftermarket companies if this trend crosses over to performance cars like the Mustang, Camaro, or Challenger.”

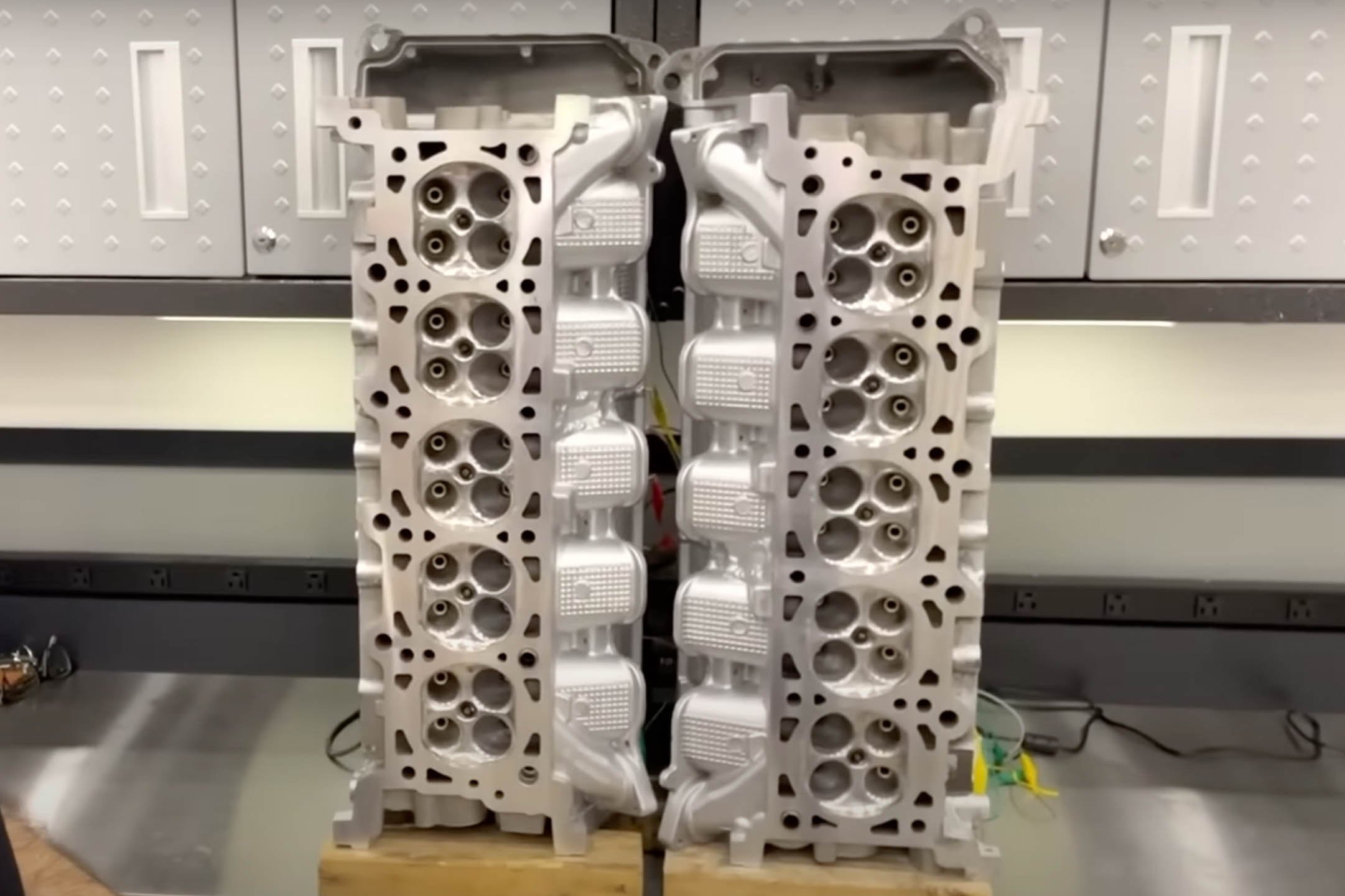

Clockwise from top left, JBA Cat4Ward headers feature 3/8-inch-thick CNC laser-cut flanges, oversized exhaust ports, and factory-style emissions-control connections.

Keeping It Legal And Improving Performance

The good news is that a shorty header — such as the JBA Cat4Ward — doesn’t give up much power when compared to long-tube headers — which are not emissions-legal because the catalytic converter would move from the OEM location. The difference is hard to quantify, Lindfors says, but he offers one example.

“On a Mustang Coyote, we saw an average horsepower gain with the Cat4Ward header and factory cats of about 11 horsepower. With long tubes and running the stock tune, we saw close to 25hp. But the car was no longer legal for road use. It used to be said that legal shorty headers were too restrictive to make power, but our years of design and testing have taught us the cats were the biggest hindrance, and those have improved over the years. The most important part is while the Cat4ward made less peak horsepower, it actually made more power in the midrange, from 3,000 to 4,500 rpm. That is where cars are most typically driven on the street, and it is something the driver can most definitely feel.

“Is there more power to be had with long tubes and cat elimination? Of course, but I would venture to say the gains of a long tube over the JBA Cat4Ward are going to be a smaller percentage than the old days of going from a cast-iron manifold to a long tube.”

Lindfors says the company was recently involved with a project on a Coyote-powered Mustang with an emissions-legal aftermarket supercharger. It was tested with both JBA Cat4Ward headers with factory converters and JBA long-tube headers without converters.

“At a level of over 700 rear-wheel horsepower, the difference between the legal headers with cats and the closed-course competition long-tube headers without cats was only seven percent — and this was on a car that was making 300 rear-wheel horsepower more than when it was when stock.”

What Goes Into The Design Of A JBA Cat4Ward Header

As high-tech as many facets of automotive engineering is, designing a new header is the simple and “time-tested method of cut-and-paste. We build the prototype header in the vehicle using mandrel-bent pieces of tubing, tacking them together to fit in the available space,” Lindfors says.

Although some companies use Computer-Aided Design (CAD) for race car headers — where an open engine compartment simplifies the process — it is not used by JBA for these street-performance headers.

“The number of data points that would have to be modeled in a modern engine compartment would be far too numerous and time-consuming,” Lindfors says. “CAD cannot be used for flow characteristics. This would require a very sophisticated, computational fluid dynamics simulation. That is not in the financial scope of most aftermarket companies. We do, on occasion, use a software parametric exhaust-modeling program, but that is generally for custom race headers that require maximum power from a specific combination within a narrow powerband.”

JBA does use a Hexagon Romer Arm, which is a coordinate measuring machine, or CMM, to scan the header after it has been designed. This 3D bend-coordinate data is then fed to CNC bending machines. Sometimes, it is also used to design cat-back exhaust systems that mimic the original exhaust system shape.

How Much Flow Is Too Much?

As you might expect, there are times when there can be too much of a good thing.

“It is possible to build a Cat4Ward-style header in which the tube diameter is too large and slows down the velocity,” Lindfors says. “This not only hurts power, but it keeps the cat from lighting off during cold start, which would cause it to fail emissions testing. With over 35 years of experience in emissions-legal header work, we have a pretty good idea of what will work with a given engine size and power output.”

(Left) In the welding jig is PN 1850S-2. It is a 1 5/8-inch Cat4Ward header, which fits certain GM trucks and SUVs from 2002-2010. The finished headers (Right) are shipped with high-quality hardware and thorough instructions for a professional, no-leak installation.

Emissions Testing

After JBA designs a Cat4Ward header that fits well, improves power, and maintains the factory catalytic-converter location for emissions compliance, it must have testing done by an independent lab to receive the Executive Order (EO).

“In our case, we use the SEMA Garage Emissions Lab, and for a few reasons,” Lindfors says. “The lab is close to our location and was updated with the latest state-of-the-art equipment just a few years back. As longtime SEMA members, we get a discount. The SEMA staff works very closely with CARB and has done some great things with expediting the process with CARB.”

The testing for OBDII and the CVS-75 FTP (Federal Test Procedure), is done on a car make and model specified by CARB after an application is submitted, looking for a model within the type that has the strictest emissions standard.

“We must then locate that vehicle model. It must have at least 4,000 miles on it. The car will have the fuel flushed out of it and refilled with ‘test fuel,’ which also meets a certain standard. The car then gets miles put on it to make sure the ECU has adapted to the test fuel and all traces of the previous fuel are gone. The test standards are to the same level that the manufacturer had to submit to when certifying the vehicles for initial sale.”

The EO process is both time-consuming and costly, Lindfors notes, and must be done each time a new model year comes out. “Even though it may seem like the vehicle and engine haven’t changed, there are often minute changes in the standards that the public never see. There can also be changes from the manufacturer to the tune, emissions equipment, or exhaust design that would require new testing.

“Other times, it’s just a matter of poring over the data for hours to validate the standards and equipment have not changed. In which case, we can get a roll-up for the new model year.”

Lindfors says the company continually has ongoing applications in the works for various vehicle brands to try to stay current, including 2020 models.

Being Emissions-legal Is Not Only A California Concern

It’s a fallacy in the industry that emissions-legal modifications are only a concern in California, Lindfors says.

“The truth is, it is against Federal law to bypass, defeat, or render ineffective any emissions device. In the past, much of the country turned a blind eye to this with a lack of emissions testing or lax standards. But over the years, many states have become more active and now use California testing procedures.”

In fact, Lindfors says, there are currently 11 states employing California emissions test standards and/or EO exemptions to certify cars through annual emissions testing.

“Additionally, the Feds — through the EPA — have begun cracking down on both manufacturers and repair shops who install non-certified or emissions-defeat devices in all parts of the country. This has resulted in millions of dollars in fines for both the manufacturer and the installation shops, and even confiscation of vehicles. We see this trend as something that will continue. Readers need to be aware of the laws and how they can affect them. There are ways to run aftermarket parts that produce power, but you’d better pay attention to the rules.”

So if you want to produce emissions-legal power and not run afoul of the law, JBA Performance fits the bill.