When you are ready to ratchet strap a car, truck, or piece of equipment to a trailer, internet research can show you that there are varying opinions about the best way to do it. And no matter who gives you their insight, their way is right — no matter what. I am not here to start an argument about the subject, but rather, to give you a few things to think about when you do strap down that valuable commodity.

With so many different opinions on the subject, I thought it prudent to get some professional insight into the subject in order to eliminate some of the confusion. To that end, I reached out to the folks at Mac’s Custom Tiedowns. Before you ratchet the first strap, there are a few things you need to consider. It goes without saying that the first thing you should do is make sure your straps are in good shape. If it has any signs of wear or fraying, get a new one(s). Also, make sure they have a sufficient load rating for what you intend to secure to the trailer.

There are many ways to secure a car to a trailer. You can use the strap through the wheel, over the wheel, or from the axles. Regardless of which method you choose, the straps should never be parallel to the vehicle. Always extend the straps outward from the car to the trailer. If possible, crossing the straps is a good idea. If crossing is not possible, at least make sure they extend outward. This helps keep the car from moving side-to-side when encountering bumps in the road.

Strap A Car How?

Watch four guys ratchet strap a car or piece of equipment and you will see at least two different ways of doing it. So I asked Mike Mehedin, media relations and account executive for Mac’s to inform me about what they feel is right and what is wrong.

Diesel Army (DA): I have seen people strap a car via axle straps, with frame hooks, through the rim, and even with single straps or “nets” over the tires. Is one way better than the others? What are the pros and cons of each way?

Mike Mehedin (MH): Whether using a standard straight-pull strap with an axle strap or using tire nets, it depends on the tie-down situation and owner preference. Both provide the same level of strength and protection for your vehicle. For most, a standard straight-pull tie-down strap with an axle strap is a great choice. Simply route the axle strap around the vehicle’s axle and run out to an anchor point or to chain extensions in stake pockets.

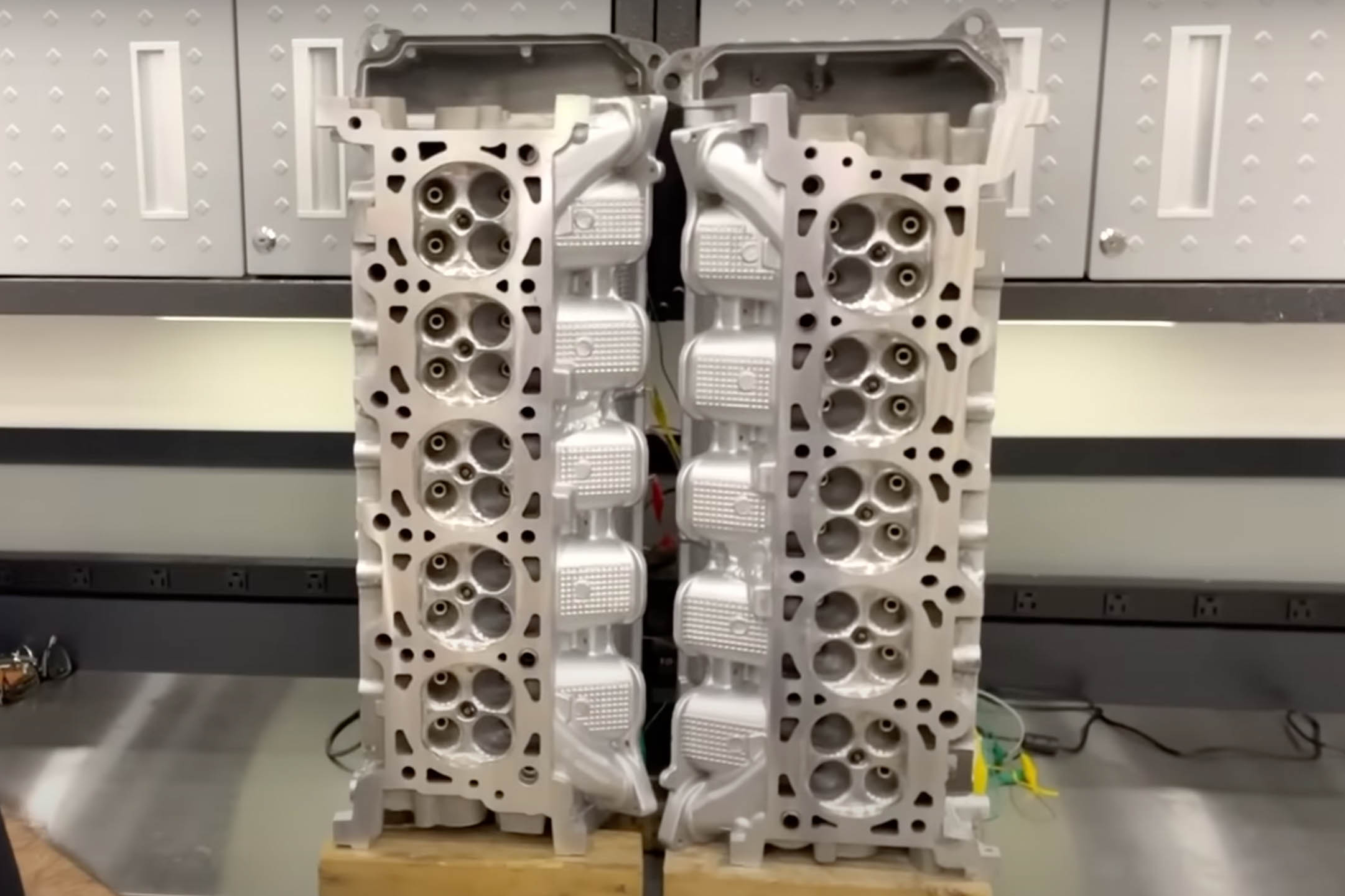

Both L-Track (left) and E-Track (right) are great options for securing any load to your trailer.

If routing through the wheel, be sure to add extra protection — like a padded fleece sleeve — around the axle strap to not only protect the strap webbing but the wheel itself. Tire nets are ideal for low-lying vehicles that would make it difficult to reach the axle. They are also a good option when trailer length is limited. While standard tie-down straps need a few feet of runout from the vehicle to secure to an anchor point, tire nets need much less runout.

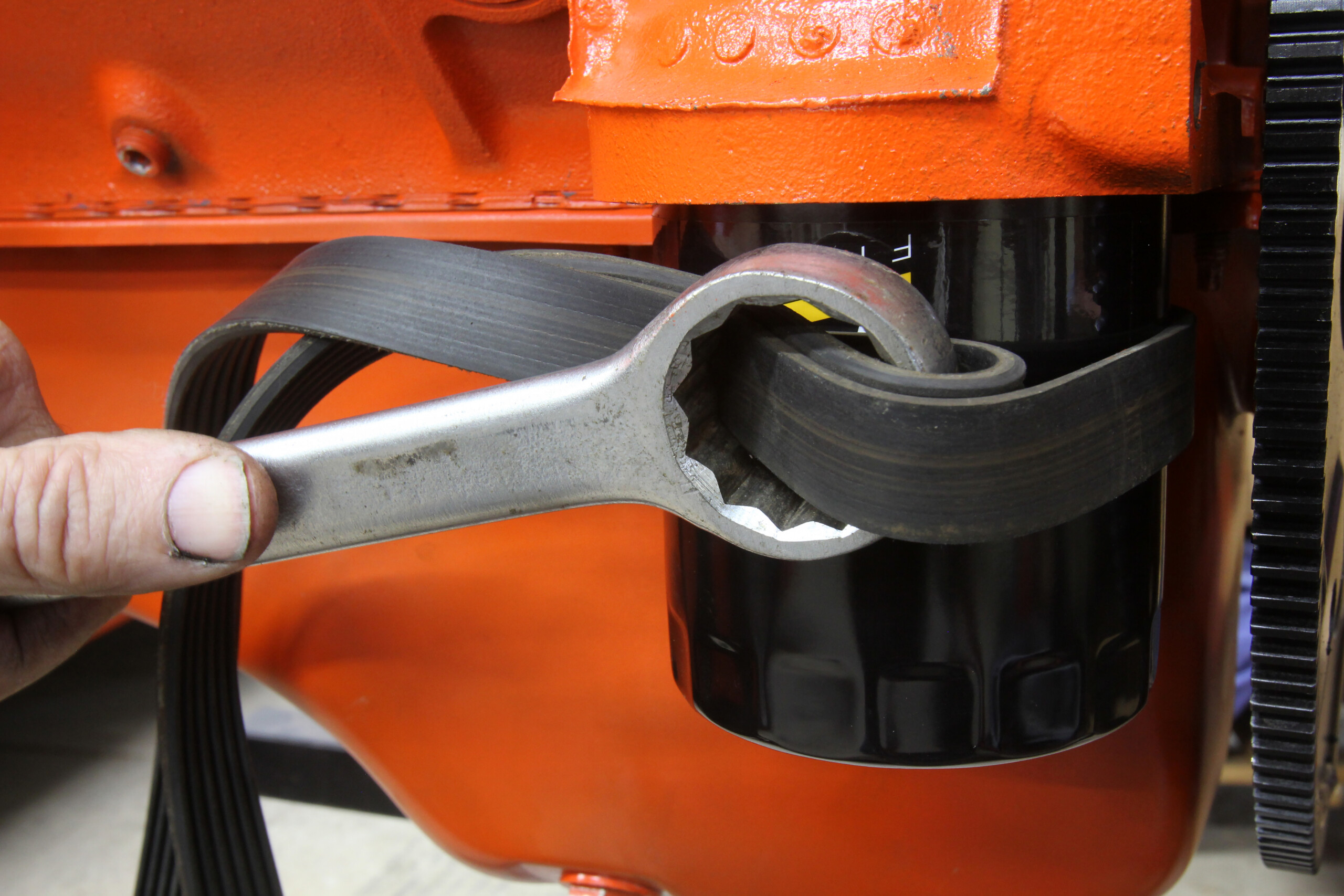

You don’t want to pull down on the suspension if at all possible. Otherwise, when you hit a bump in the road, the suspension compresses, and the ratchet strap could loosen. When the suspension returns to its original position, it will “shock” the strap, which could make it come loose or possibly break. Corvettes are very common for using a Mini J-Hook or T-Hook on the frame. There is a front and rear slot on those particular cars. They then pull forward and rearward when they strap the car down.

Weighted Reality When You Ratchet Strap A Car

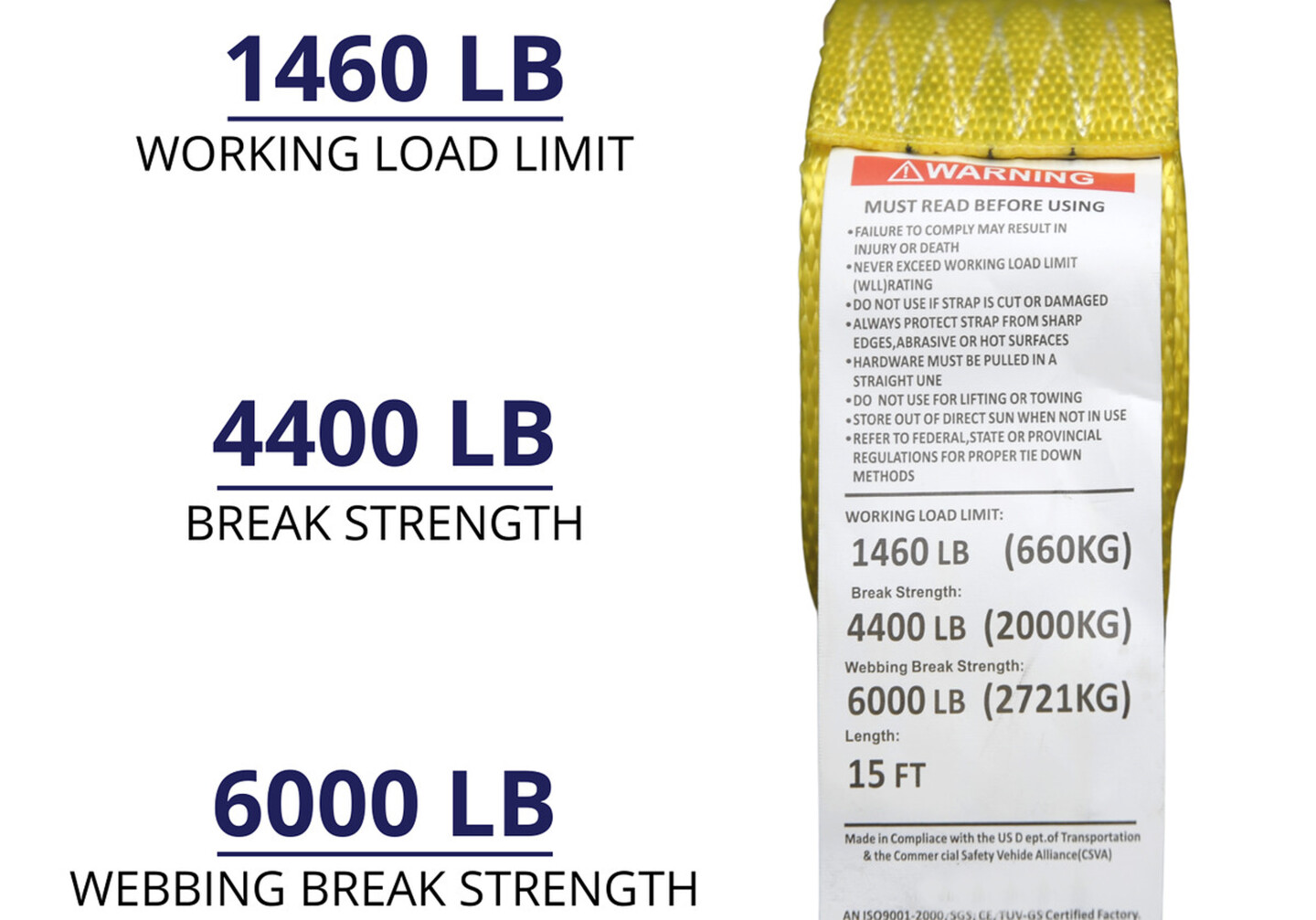

DA: How should someone choose the proper weight-rating ratchet straps and what is the weight rating, the shock breakage, or the stress breakage number?

MH: There are two numbers to be mindful of when determining tie-down strap strength: the breaking strength and the working load limit. The breaking strength is the weight at which a strap fails in a straight pull. The working load limit is when a strap fails under a dynamic load (the weight of a vehicle in motion). For example, a vehicle might have a static weight of 3,000 pounds, but its dynamic weight could be as heavy as 9,000 pounds. The working load limit should be 1/3 of the breaking strength. Therefore, a 3,000-pound vehicle needs a minimum 9,000-pound capacity tie-down strap. All Mac’s 2-inch tie-down straps have a breaking strength of 10,000 pounds with a working load limit of 3,333 pounds.

DA: What is the reason for different strap hooks (Flat vs. Twisted Wire) Again, is one better than the other?

MH: We recommend hooks with a thumb-release clip. This ensures the hook stays attached to the anchor point in the event the webbing loses tension. A unique hook to Mac’s is the Twisted Snap Hook. Its unique design takes the “twist” out of the webbing when attaching to an anchor point.

A Ratchet Strap For The Long Haul

DA: What is the life expectancy of a typical strap?

MH: Life expectancy depends on the amount of use. Straps that are used on a daily basis in extreme weather and temperatures will undoubtedly show wear and tear faster than straps that are used only on the weekends. That’s why it is important to check your straps on a consistent basis for obvious — and not-so-obvious — signs.

Although there are various styles of hooks to choose from, using a hook with a “latch” is a good idea as it ensures the strap does not come unhooked until you want it to.

DA: What is the best way to care for a strap?

MH: Over time, dirt and grime can get built up in the ratchet gear set. Simply submerge your ratchet into a degreaser and warm water mixture. Blow it off or allow it to air dry. Then add lubricant (i.e., dry graphite) into the gear-set on each side. Dirt and grease can embed the webbing fibers and lead to early wear and tear. Saturate the webbing in a solution of Simple Green and warm water solution, scrub with a stiff bristle brush, and then rinse. The important thing to remember for the ratchet and the webbing is to hang them up to dry. Don’t put them back in the trailer wet and don’t hang them out in the sun to dry.

Tracking Your Load

DA: I also want to talk about E-track (i.e., proper mounting to the trailer, how to properly use it, weight ratings, and the pros and cons).

MH: E-track and L-track are the two most popular options. Both are versatile in the sense that they can be easily mounted almost anywhere in the trailer: floor, wall, ceiling. Anywhere it’s needed. A variety of fittings are available depending on what you’re securing. E-track, however, does have its flaws when compared to L-track. Aside from its size being larger and creating a potential trip hazard on a trailer floor, E-track has a closed center channel. Dirt and trash can get into the track and make it difficult to get out. L-track profiles have an open center channel and can be easily cleaned of dirt and debris. Also, E-track fittings are designed to be pulled vertically or in line with the track. L-track can be pulled from any angle. Both E-Track and L-Track fittings are rated for 5,000 pounds minimum breaking strength.

Although there are a lot of things to consider when securing a vehicle to a trailer, hopefully, these few tips will help ensure your car doesn’t leave your trailer before you want it to come off.